Interview Key Social Issue | Mitigation of climate change

Reducing the automotive industry's CO2 emissions

Casted automotive parts manufacturer KIRIU taking on the challenge of carbon neutrality at its manufacturing sites

Against the backdrop of climate change issues and technological innovations such as CASE*, the automotive industry is at a once-in-a-century turning point. In order for automobiles to remain an essential part of society, decarbonization efforts pose a challenge for the entire automotive industry, and the Sumitomo Corporation Group, which operates a wide range of businesses within this industry from upstream to downstream, is actively promoting these efforts.

Brake components made by KIRIU CORPORATION, a casted automotive parts manufacturer wholly owned by Sumitomo Corporation, will continue to be essential in the new automobile society symbolized by electrification and autonomous driving. KIRIU conducts business operations under its mission, “to contribute to the realization of a highly motorized society, by providing safety and comfort to our valued customers through KIRIU's Monozukuri (craftsmanship).” What are the challenges facing KIRIU and what does it need to do on the front line of its operations to overcome them and provide new value? Here, we will introduce the thoughts of the Sumitomo Corporation staff member in charge of KIRIU's project for carbon neutrality.

* An acronym for Connected, Autonomous, Shared & Services, and Electric

Interviewee

Kosuke Hatanaka

Automotive Manufacturing Business Dept. No.1

Joined the Company in 2013. He was involved in trading new vehicles in the Middle East, managing automobile dealerships, and creating next-generation businesses that use batteries. After working at Sumitomo Corporation (Shanghai) , he joined the Automotive Casting Business Team in November 2021, where he plays a central role in KIRIU's project for carbon neutrality.

Why

Global growth also poses major environmental impacts

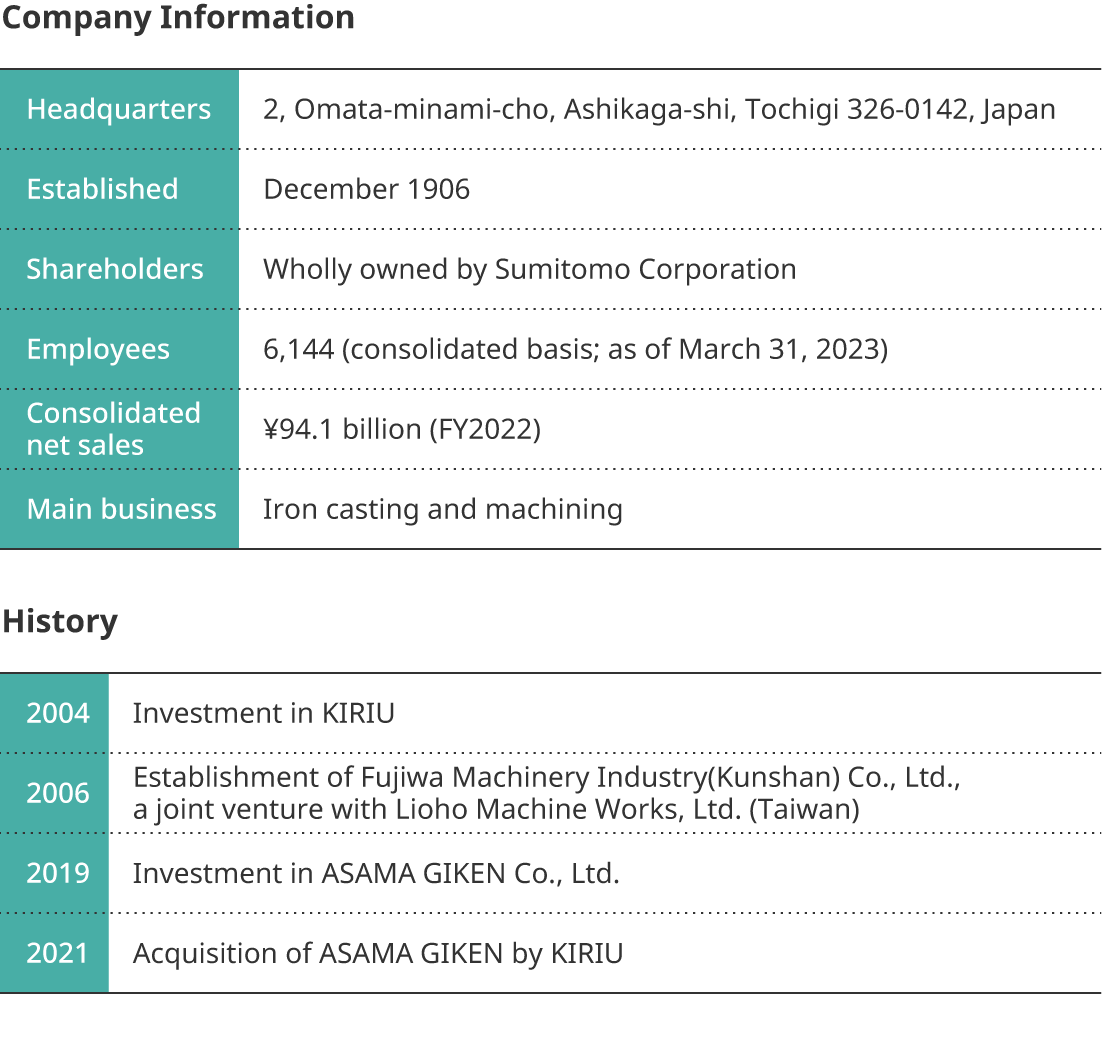

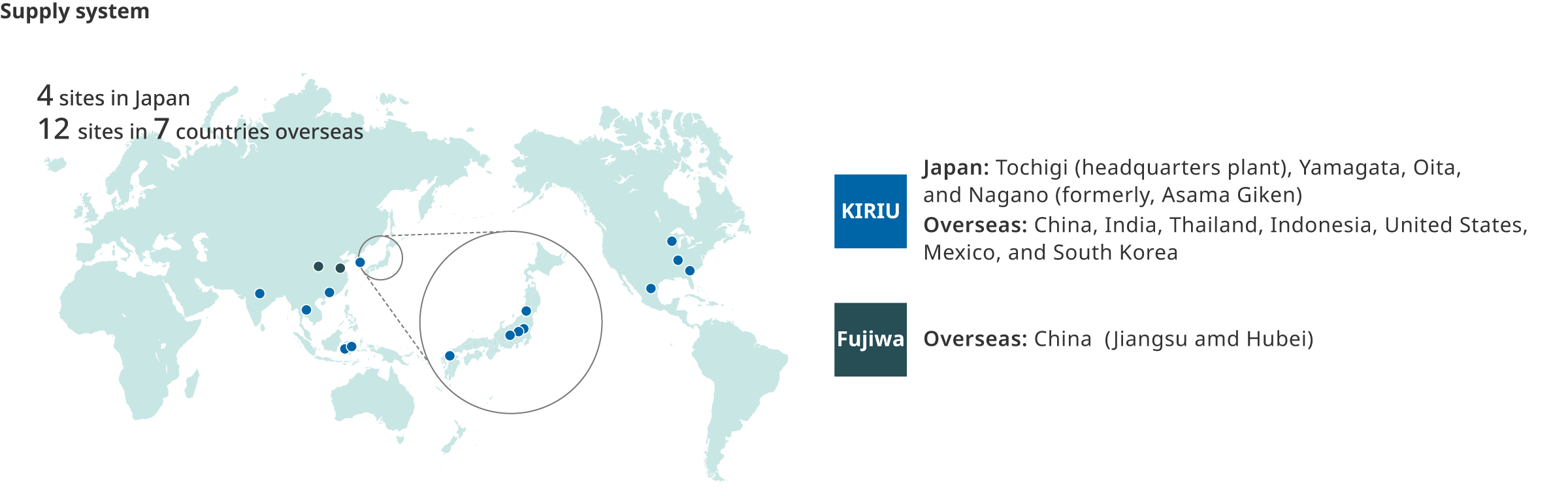

KIRIU, which has been in business for more than a century since 1906, is a casted automotive parts maker that manufactures and sells important brake-related safety components such as brake rotors. Sumitomo Corporation invested in KIRIU in 2004 and promoted its globalization by leveraging our strengths in overseas network, management human resources, and funding capabilities. Today, KIRIU has grown into a multinational corporation with manufacturing bases in eight countries located in Asia and North America.

On the other hand, the casting business requires a production process with a large environmental impact as it involves melting, solidifying, and processing iron at high temperatures. Sumitomo Corporation is committed to mitigating climate change throughout the Group and has set a target for carbon neutrality by 2050. In 2022, KIRIU had the highest Scope 1 and Scope 2 emissions among the Group (Sumitomo Corporation and subsidiary businesses) excluding the thermal power generation business and fossil fuel upstream business. In order for KIRIU to continue to grow sustainably, it is critical that the company shifts to a production process with a low environmental impact and addresses the needs of a decarbonized society.

What&How

KIRIU's path to decarbonization

In the manufacturing industry, QCD, which stands for quality, cost, and delivery, was a source of competitiveness, but QCDE, which adds environment, has become indispensable as we are moving toward a decarbonized society.

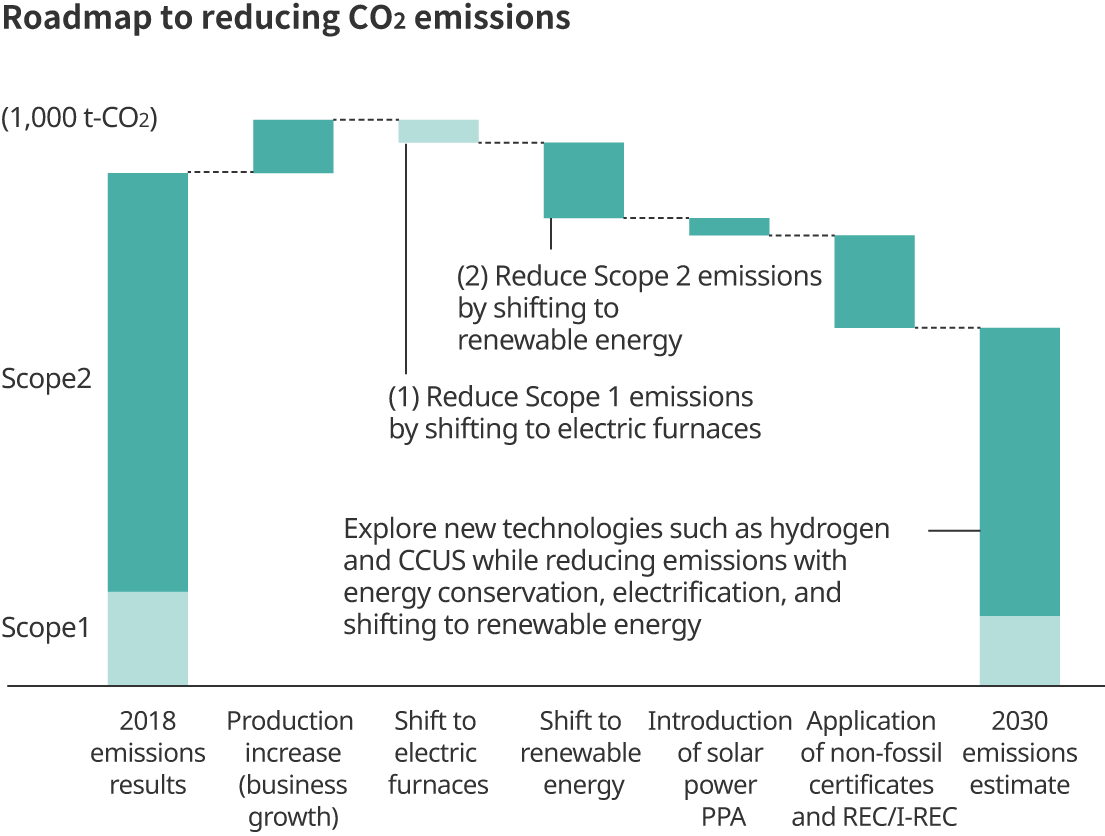

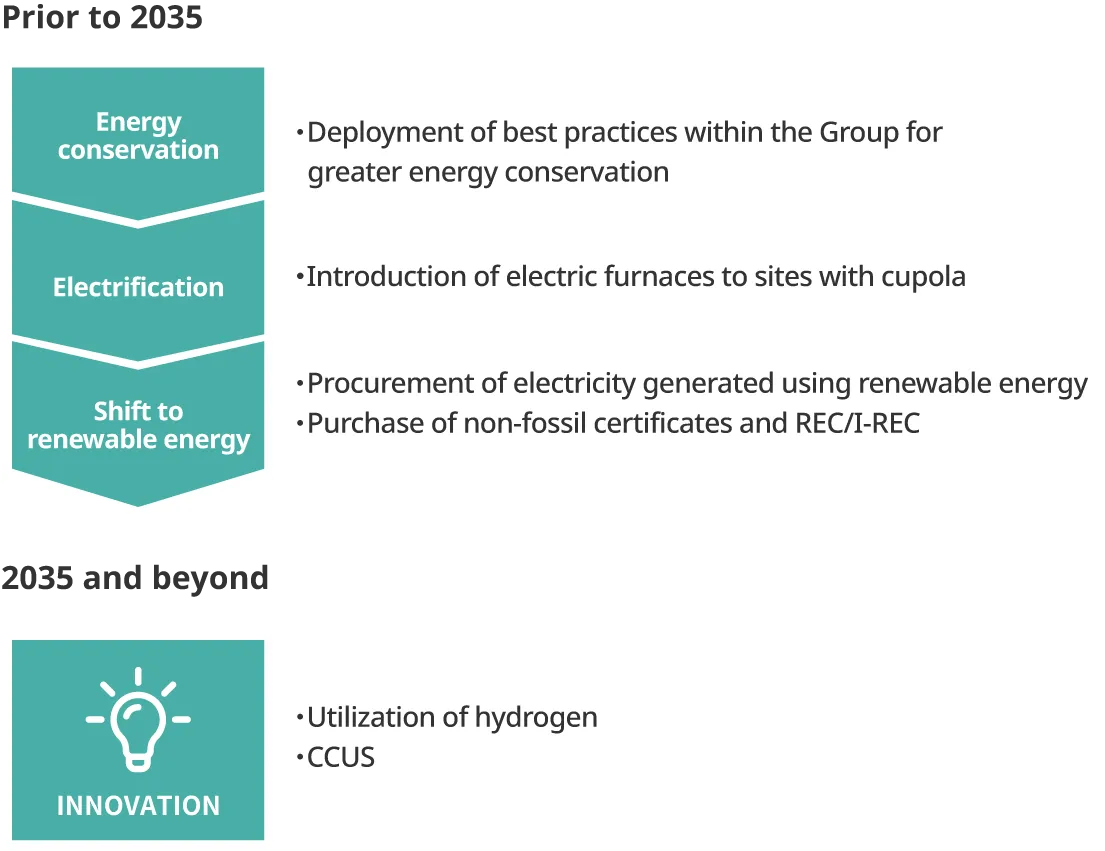

In April 2023, KIRIU also formulated a roadmap for achieving carbon neutrality by 2050 and launched a strategy consisting of three steps: (1) energy conservation, (2) electrification, and (3) shift to renewable energy.

For each step, KIRIU has started initiatives including: (1) finding opportunities for further improvement in the production process with the support of group company Sumitomo Shoji Machinex Co., Ltd. for energy conservation; (2) introducing electric furnaces that significantly reduce CO2 emissions in the production process at the Ashikaga Headquarters Plant for electrification; and (3) switching to electricity from renewable energy and consulting on the purchase of REC*1 and I-REC*2 with the Energy Innovation Initiative (EII)*3 , Sumitomo Mitsui Finance and Leasing Co., Ltd. (SMFL), and Summit Energy Corporation for the shift to renewable energy. In addition, to take on the challenge of implementing new technological innovations such as hydrogen and Carbon dioxide Capture, Utilization and Storage (CCUS) in the future, Sumitomo Corporation is communicating with the members of related departments within the company.

*1 An acronym for Renewable Energy Certificate. An electricity certificate adopted as the standard in North America

*2 An acronym for International Renewable Energy Certificate. An electricity certificate widely available globally

*3 A cross-functional business organization that engages in next-generation business development in the fields of decarbonization and next-generation energy

Electric furnace at the Ashikaga Headquarters Plant (completed in April 2023)

Shift from cupola to electric furnace

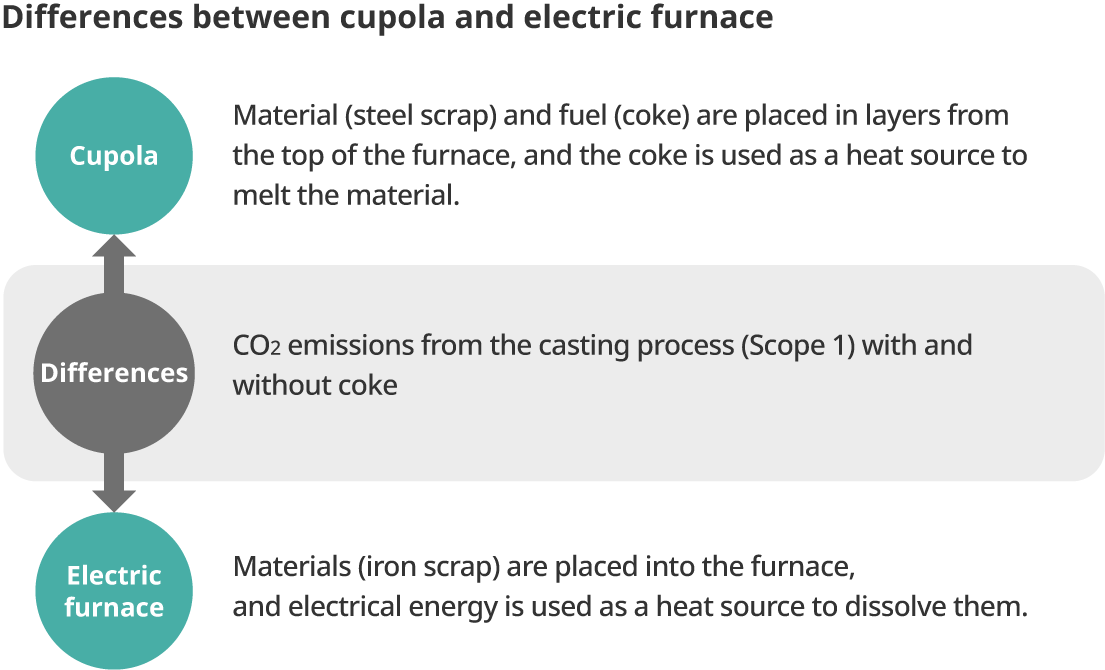

A cornerstone of KIRIU's carbon neutrality strategy is the introduction of electric furnaces at the Ashikaga Headquarters Plant. In the casting process, raw material iron scrap is melted down in a melting furnace, but the conventional cupola furnace uses coke as a heat source to melt the iron, which emits a large amount of CO2 during manufacturing. Therefore, KIRIU decided to switch to electric furnaces with a low environmental impact.

Electric furnaces are already being introduced at its overseas production plants, and the Ashikaga Headquarters Plant is the second plant in Japan to install these, following the Oita Plant. The benefits of an electric furnace involve not only a reduction in CO2 emissions but also stable product quality and an improvement in the working environment, which provides many positive factors for the sustainable growth of KIRIU.

Use of renewable energy and the next phase of strategy

Direct emissions from plants (Scope 1) can be reduced by switching to electric furnaces, but indirect emissions from electricity use (Scope 2) remain; therefore, the next challenge is to replace the electricity used with electricity from renewable energy. Specifically, KIRIU is working to procure electricity generated from renewable energy, introduce solar power purchase agreements (PPA) on- and off-site, and purchase REC/I-REC and non-fossil fuel certificates. Since accessibility to renewable energy differs depending on the country or region, KIRIU is promoting decarbonization measures in line with regional uniqueness, for example, switching to electricity from renewable energy in India and Mexico, and introducing on-site solar PPAs in Thailand.

Going forward

Taking on the challenge of low environmental impact manufacturing as a member of an integrated trading company

Since joining the Company in 2013, I have been consistently involved in the automotive business. As a member of an integrated trading company, I am deeply involved in manufacturing and I face the challenge of reducing its environmental impact.

The automotive industry is currently at a major turning point against the backdrop of climate change. How will the automotive industry evolve so that automobiles continue to be a necessary part of society? I believe that addressing this issue is not something that can be achieved by automobile manufacturers alone, but rather a challenge for the entire value chain. With KIRIU's production floor, we hope to stand between the market and the production front line and see what kind of value and innovation we can create. Through the evolution of sustainability management one step ahead of the industry, we would like to demonstrate the unique value of an integrated trading company that engages in manufacturing.

Carbon neutrality initiatives are a challenge yet to be answered, but we have received support from our various departments and group companies. By injecting the Group's decarbonized and low-carbon solutions into KIRIU's manufacturing sites, we will create critical momentum that cannot be generated by the department in charge alone. Seeing the scale and speed at which this momentum is growing, I feel once again the thrill of working for an integrated trading company.

Interviews

- ../card/forest-interview.html

- ../card/storage-battery-interview.html

- ../card/bio-interview.html