Interview Key Social Issue | Mitigation of climate change

Biomass energy development

Striving to develop new carbon-free energy from wood pulp

There is worldwide demand for the production and stable supply of carbon-free energy, such as hydrogen and ammonia, as an alternative to fossil fuels, as this is essential to realize a carbon-neutral society. While Sumitomo Corporation works on multiple projects for hydrogen and ammonia, the Company is seeking to address the issue of climate change by producing new carbon-free energy. Together with Nippon Paper Industries Co., Ltd., which we have been doing business with for more than 50 years, we will contribute to reducing CO2 by producing bioethanol from wood pulp as a raw material for jet fuel. This could be one of the most advanced endeavors in the world as the project also seeks to produce non-edible biomass by making use of abundant forest resources in Japan. This project would not have been possible without the firm trust we had established with our business partners over the last several decades and a history of tenacious and wide-ranging studies on new business development in the field of next-generation biotechnology. The following is an interview with the members who have been leading this unprecedented project.

Interviewees

Natsuki Omori

Biomass Energy & Materials Department

Joined Sumitomo Corporation in 1994. He was in charge of wood pulp imports and domestic sales during his time with the Pulp Team of Pulp & Paper Department No. 2. After being transferred to the Cement Department in 2008, he was assigned to a biomass-related development project in Lampung, Indonesia in 2013. After working in the biomass-related business, in 2021 he was placed in charge of the wood pellet import business and next-generation biomass material and fuel development in the Biomass Pellet Team of the Biomass Energy & Materials Department.

Masato Yokoyama

Biomass Energy & Materials Department

Joined Sumitomo Corporation in 2019. He was assigned to the Wood Chip Team of the Biomass Materials & Fuels Department and managed wood chip imports and exports. In 2021, he moved to the current Biomass Pellet Team of the Biomass Energy & Materials Department. In addition to importing wood pellets, he is involved in developing next-generation biomass materials and the fuels business.

Why

Bioethanol made from non-edible resources attracting worldwide attention

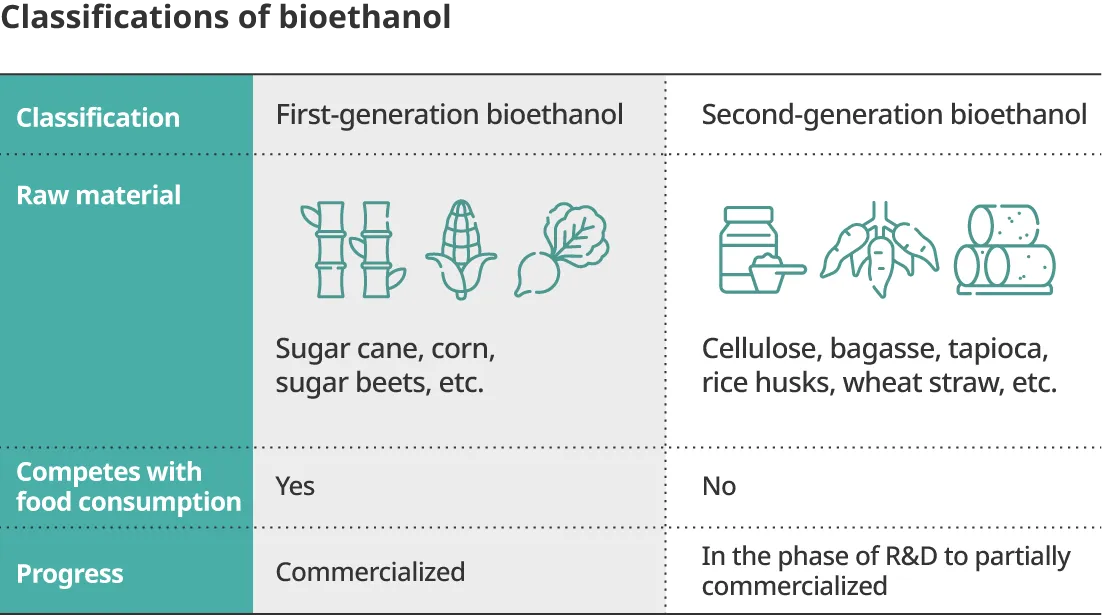

Bioethanol is currently attracting attention in countries worldwide striving for a carbon-neutral society as a renewable energy source and as feedstock for biofuels such as SAF*1 and chemicals with low environmental impact. Bioethanol produced from edible biomass such as sugar, starch, and vegetable oil is called “first-generation bioethanol.” Meanwhile, cellulosic bioethanol made from inedible biomass that does not compete with food consumption, such as woody biomass and bagasse (i.e., the sugarcane residue after sugar production), is classified as “second-generation bioethanol.” In particular, the latter type of woody biomass has the potential to tackle various issues in Japan, including utilizing abundant domestic forest resources, ensuring energy security, and improving energy self-sufficiency.

*1 An acronym for sustainable aviation fuel. This refers to an aviation fuel that significantly reduces CO2 emissions compared to conventional fuels throughout its life cycle, from production and collection to manufacturing and combustion, and can utilize existing infrastructure without modification.

What&How

Joint study together with Nippon Paper Industries and Green Earth Institute

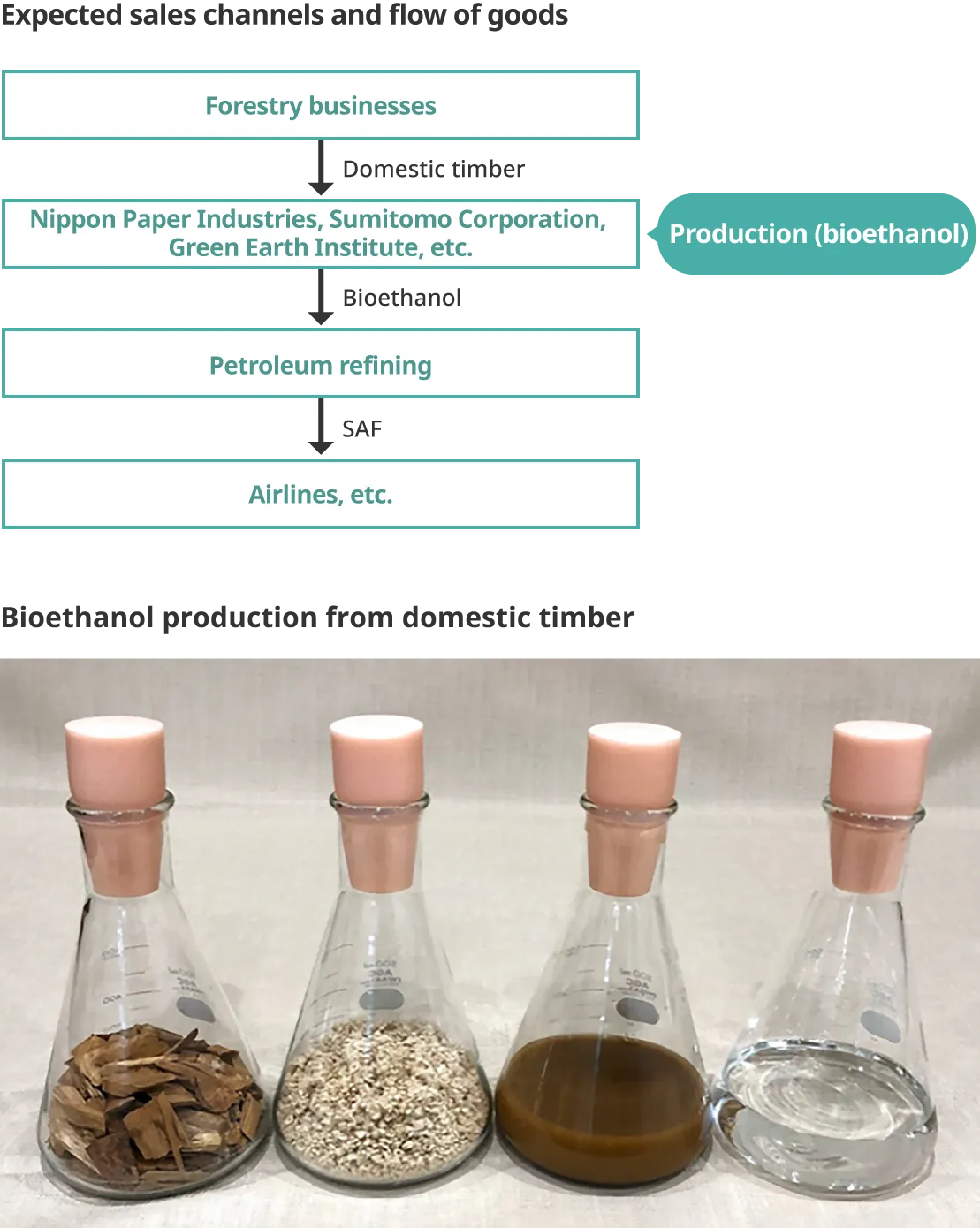

Sumitomo Corporation, together with Nippon Paper Industries and Green Earth Institute Co., Ltd., has begun a study on the commercial production of Japan's first cellulosic bioethanol made from woody biomass and its development into biochemical products. The project aims to produce bioethanol from domestic wood resources with an annual production capacity of tens of thousands of kiloliters.

The production of bioethanol from non-edible resources, especially wood pulp, is a global pioneering initiative. Not only does it contribute to decarbonization as an alternative to petroleum fuels but the use of non-edible resources realizes lower CO2 emissions and has lower environmental impact compared to mainstream bioethanol production from corn and sugar. In addition, by using black liquor obtained during pulp production, we aim to achieve exceedingly low CO2 emissions compared to other fuels. Furthermore, by effectively utilizing domestic thinned wood, it will also lead to the conservation of forest assets in Japan.

This bioethanol will be used mainly as a raw material for domestically produced SAF, for which demand is expected to increase rapidly in the future. We also plan to consider the establishment of a carbon recycling system, such as capturing and utilizing CO2 produced as a by-product of bioethanol production, and converting the residue of the fermentation process into feed and fuel.

New technologies are needed to use our bioethanol, which we aim for commercial production, as jet fuel. This is an area that oil companies are working on. To realize a recycling-oriented carbon-neutral society, various challenges are underway simultaneously around the world. It is exciting to think that we are playing a part in this, and we strongly wish to achieve success in the field at all costs.

Bioethanol on the far right is produced through the process of using the leftmost wood chip to create pulp and then saccharification fermentation culture media (courtesy of Nippon Paper Industries and Green Earth Institute)

Members discussing the direction of the project at a training camp (Nippon Paper Industries, Green Earth Institute, and Sumitomo Corporation)

Achieving win-win collaboration based on a strong relationship

Our collaboration with Nippon Paper Industries began with the import of wood chips from South Africa approximately 50 years ago, and since then we have continued to collaborate and trade mainly in the afforestation business in South Africa and South America. The second-generation bioethanol business was made possible based on the solid trust we have earned through collaboration over many years. Their expectation toward our knowledge and know-how in group company management also helped to make the collaboration happen.

Since this project will make effective use of idle pulp production facilities in Japan, it is expected to contribute not only to mitigating climate change but also to solving the problems faced by the paper industry and revitalizing the industry as a whole.

Continuing to take on the challenges of commercialization by harnessing the collective strengths of Sumitomo Corporation

After the conclusion of the basic agreement in February 2023, there are still many challenges to address before the start of bioethanol production, but as we seek to work out these issues, the underlying strengths of Sumitomo Corporation as an integrated trading company are helping to create new businesses. The Energy Innovation Initiative (EII)*2, an individual business organization newly established in April 2021, brings together experts in energy and infrastructure, as well as other fields, and provides engineering advice to Nippon Paper Industries and Green Earth Institute from time to time. In addition, since the Group has specialists in various other fields, we are collaborating with the Green Chemical Business Development Department, and with SC Foods Co., Ltd. and the AgriScience Department on the effective utilization of residues generated in the bioethanol production process.

Sumitomo Corporation's creativity and connections between businesses as well as its abundance of specialists undoubtedly serve as a cornerstone for supporting sustainable business growth.

*2 A cross-functional business organization that engages in next-generation business development in the fields of decarbonization and next-generation energy

Going forward

Hoping to bridge to the next generation businesses that go beyond win-win relationships

I have a strong attachment to this project. This year, we finally reached a point to where we could issue a press release on the progress made. This was only possible thanks to the diligent work of our many tenacious colleagues, including those who have already left the department, seeking to do something innovative using wood resources. I feel a flood of emotions when it comes to working on a new business with Nippon Paper Industries because I have had a deep relationship of trust with them for many years. This business will bring many benefits not only to the three collaborating companies but also to the domestic forestry industry, the aviation industry, and the global environment. I personally believe that we can achieve a “win to the 10th power” that goes beyond just a win-win relationship. Since this is a long-term project, I hope to be a bridge to the next generation so that Mr. Yokoyama's generation can powerfully grow the business. I would like it to eventually develop into a business that can support the sustainable development and decarbonization of Japanese industry.

Working to resolve social issues through collaboration with Nippon Paper Industries

Based on my specific research of wood at university, since joining the Company, I have been studying new ways to utilize woody biomass together with my colleagues and members of the Wood Resources Business Department. I am very pleased that these studies have borne fruit and that the commercial production of cellulosic bioethanol will pave the way for pulp utilization outside of papermaking. In addition, my first client after joining the Company was Nippon Paper Industries, so I feel a deep connection and am excited to be able to work together to help solve social issues. In the future, I would like to not only realize this business but also seek business opportunities in the biochemical field, such as producing plastic bottles derived from wood chips.

Interviews

- ../card/CO2-reduction-interview.html

- ../card/forest-interview.html

- ../card/storage-battery-interview.html