Feb. 08, 2024

Concluded Joint Development Agreement for Production of Sustainable Aviation Fuel (SAF) from Woody Biomass in the US- Helping decarbonize the aviation industry by producing low-carbon SAF -

Sumitomo Corporation, through Sumitomo Corporation of America (hereinafter collectively referred to as the "Sumitomo Corporation Group"), has entered into a joint development agreement (hereinafter referred to as the "Agreement") with Strategic Biofuels, a developer of renewable fuels, to produce woody biomass-based sustainable aviation fuel (SAF) in the state of Louisiana, USA.

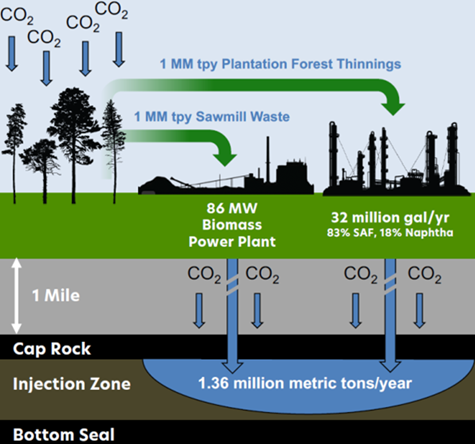

Under the Agreement, the two parties will employ a process known as the "gasification-FT process” to jointly develop the production of SAF from woody biomass. The gasification-FT process involves converting woody biomass into synthesis gas that is then used in the FT process (*1) to produce SAF and naphtha. The CO2 emitted when producing SAF is captured and stored (CCS*2), as is the CO2 generated from the biomass power station installed within the plant (BECCS*3). Net negative emissions across the entire supply chain are achieved through integrated SAF production that combines these elements (the gasification-FT process, CCS, and BECCS).

Scheduled to begin commercial production in 2029, this project should produce approximately 120,000 kiloliters of SAF and naphtha per year; a second and third plant may be constructed at some future point.

The Sumitomo Corporation Group will have offtake rights to the SAF and naphtha produced as well as to the associated state and federal renewable fuel credits under the terms of the Agreement. The SAF is expected to be sold to airlines and fuel suppliers in the US, and it should prove useful in helping decarbonize the US aviation industry, whose stated goal is meeting 100% of aviation fuel demand with SAF by 2050.

<Conceptual rendering of the project>

<Image of plant layout>

SAF to decarbonize the aviation industry

In contrast to conventional jet fuel refined from crude oil, SAF is made from biomass-derived raw materials, waste materials, and waste cooking oil. It is regarded as a sustainable aviation fuel that can utilize existing infrastructure without modification and that emits far less CO2 than conventional fuels throughout its life cycle from production and collection to combustion. The International Air Transport Association (IATA) has set a goal of virtually eliminating greenhouse gas emissions in the aviation industry by 2050. Nevertheless, only a limited number of SAF production technologies are currently in commercial use and, with growing demand expected to greatly exceed supply in the future, increasing production by diversifying production technologies has become a pressing issue.

Sumitomo Corporation Group’s initiatives in the SAF sector

The Sumitomo Corporation Group has positioned "climate change mitigation" and "circular economies" as important social issues and is accordingly taking on the challenge of creating new businesses by establishing decarbonized, circular energy systems. The Group is working to develop SAF production and sales globally, seeing SAF as both an important means of achieving carbon neutrality in the aviation industry by 2050 and as a medium- to long-term business opportunity. It will help decarbonize the aviation industry and ensure a stable supply of low-carbon biofuels by participating in and pursuing multiple projects that use raw materials and production methods considerate of the characteristics of specific locales, including the US, the world's largest market of jet fuel and a country with extensive government support measures.

- FT process:The Fischer-Tropsch process is a series of processes for synthesizing liquid hydrocarbons from carbon monoxide and hydrogen (synthesis gas) using a catalytic reaction.

- CCS:Abbreviation for Carbon dioxide Capture and Storage; the separation and collection of emitted CO2 from other gases and the storage and injection of said CO2 deep underground.

- BECCS:Abbreviation for Bioenergy with Carbon Capture and Storage; a technology that combines CCS and biomass energy.