Nov. 10, 2025

Sumitomo Corporation

Toshiba Information Systems (Japan) Corporation

Sumitomo Corporation and Toshiba Information Systems Jointly Develop a Non-Contact Liquid Leak Detection System- Digital transformation (DX) of water and chemical leak detection for real-time monitoring, contributing to enhanced factory safety and efficiency-

Sumitomo Corporation (Head Office: Chiyoda-ku, Tokyo; Representative Director, President and Chief Executive Officer: Shingo Ueno) and Toshiba Information Systems (Japan) Corporation (Head Office: Kawasaki City, Kanagawa Prefecture; President: Ken Nemoto; hereinafter "Toshiba Information Systems") have jointly developed a new non-contact liquid detection system, the SWIR 3D Camera System for Water and Chemical Leak Detection (hereinafter "the System").

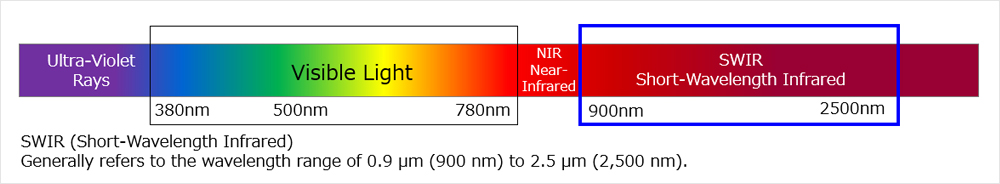

Leveraging the characteristics of short-wavelength infrared (SWIR), the System enables non-contact, wide-area, real-time and automatic detection and identification of liquids such as water, chemicals and oils – capabilities that were difficult to achieve with conventional methods. Patent application for the System was completed in September 2025, with sales scheduled to begin after August 2026.

Sumitomo Corporation led the product planning, combining the technologies of an investee company based in Taiwan and a domestic manufacturing partner. Toshiba Information Systems developed the proprietary liquid-detection algorithm "Liquidseeker" that powers the System. Following the launch, the companies will initially focus on deployment in semiconductor manufacturing plants, with plans to expand into a wide range of industries, including pharmaceuticals and chemicals, and eventually overseas through Sumitomo Corporation's global network.

Challenges in Conventional Leak Detection

In factories and warehouses, leak monitoring has traditionally relied on leak detection tape. However, these tapes are prone to detachment and disconnection, requiring regular replacement and repair, adding maintenance workload and posing safety concerns during inspection work. In addition, since the tape must be in direct contact with the liquid to detect a leak, early detection is difficult when the leak occurs a distance from the tape.

Because the new System detects liquids across wide areas without contact, it resolves these issues while also streamlining inspection operations.

System Features and Expected Benefits

The newly developed SWIR 3D Camera System for Water and Chemical Leak Detection offers four key features:

- Detection of water, chemicals and oil with a single unit

The System accurately identifies the presence of unwanted liquids such as leaks. As it has no physical detection tape, there is no risk of detachment or disconnection, reducing maintenance costs and allowing usage in locations where tape cannot be used. - Early detection of even the smallest leaks

The System can detect liquid volumes as small as a few drops, enabling early detection of abnormalities. - Remote detection from up to three meters away

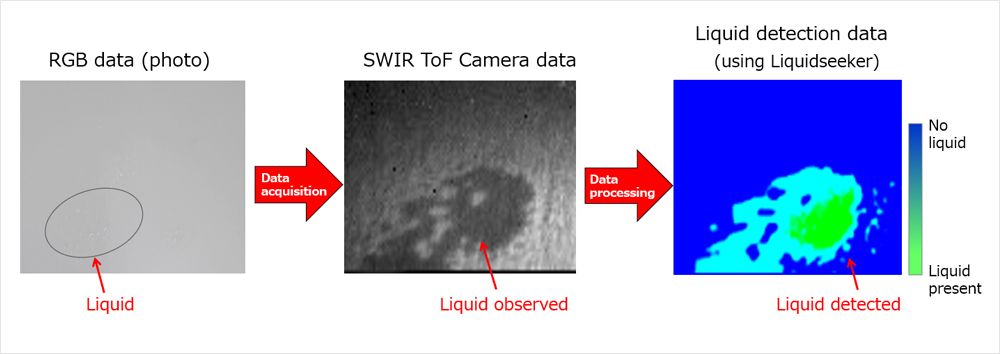

Continuous, real-time monitoring from up to three meters away allows non-contact coverage of large equipment areas. - 3D observation using distance information

By applying a leak-detection algorithm based on the characteristics of SWIR, the System not only determines liquid type but also provides highly accurate localization of leaks.

The System can be applied to a wide range of facilities and equipment, including semiconductor manufacturing and inspection equipment, warehouses, factory and plant facilities, research institutes, telecommunications base stations, medical facilities and data centers.

Expected benefits include reduced maintenance costs through replacement of conventional leak detection tapes, enhanced safety and operating efficiency through early leak detection in production equipment, machinery and piping, and faster root-cause identification through liquid classification. Collectively, these contribute to stable operation of production sites and plants, advancing the digital transformation (DX) of leak detection operations and supporting safer, more efficient manufacturing environments.

About the SWIR 3D Camera System for Water and Chemical Leak Detection

The System consists of the SWIR ToF Camera System for Water and Chemical Leak Detection developed by Sumitomo Corporation and the "Liquidseeker" leak-detection algorithm developed by Toshiba Information Systems.

- SWIR ToF Camera "3D Camera System for Water and Chemical Leak Detection" (Sumitomo Corporation)

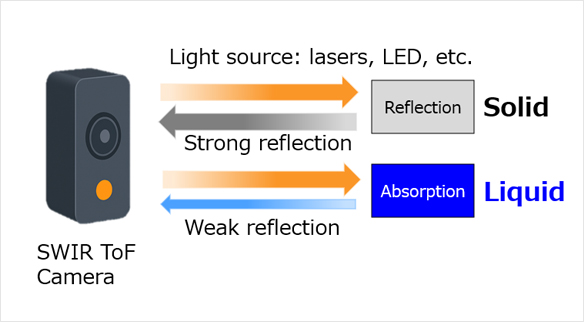

- SWIR technology distinguishes between materials based on their absorption and reflection characteristics, even when such differences are invisible in ordinary light. Because water appears black under SWIR and the imaging is unaffected by fog, smoke or dust, stable sensing is possible even in harsh environments. This enables detection of liquids, foreign substances and material differences that conventional cameras struggle to capture.

- Liquid-Detection Algorithm "Liquidseeker" (Toshiba Information Systems)

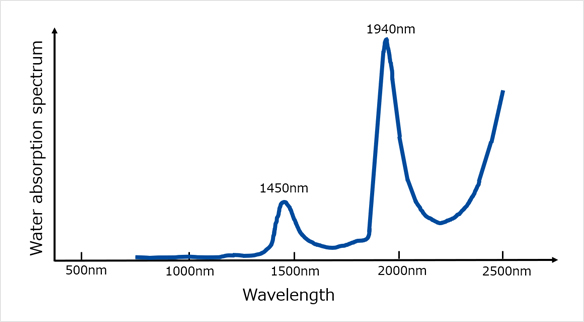

- Liquidseeker detects liquids by utilizing the principle that water absorbs light at specific wavelengths. Combined with the SWIR ToF Camera, it enables non-contact liquid detection.

Water absorption spectrum

Water detection principle

Sales and Exhibition Information

| Sales launch | : | Scheduled for after August 2026 |

| Pricing | : | Open (details available on request) Toshiba Information Systems will showcase “Liquidseeker” at IIFES 2025, held at Tokyo Big Sight from November 19 (Wed.) to 21 (Fri.), 2025. A live demonstration of the “SWIR 3D Camera System for Water and Chemical Leak Detection” will also be presented. |

IIFES 2025 Overview

| Dates | : | November 19 (Wed.) – 21 (Fri.), 2025 |

| Hours | : | 10:00–17:00 |

| Venue | : | Tokyo Big Sight, East Hall 4 Toshiba Group Booth (Booth No. 4-03) |

Media Inquiries

- Sumitomo Corporation Corporate Communications Department, Marketing Communication Team

- E-mail: mktg-communication@sumitomocorp.com

- Corporate Website:https://www.sumitomocorp.com/ja/jp/

- Toshiba Information Systems Public Relations, Technology Division

- Tel: +81-80-9466-7524

- Website: https://www.tjsys.co.jp/

- Liquidseeker: https://www.tjsys.co.jp/lsi/liquidseeker/index_j.htm

* Company and product names mentioned herein may be trademarks or registered trademarks of their respective owners