Global Cases

Delivering sugar from Tanegashima to across Japan Shinko Sugar Mill advances the local sugarcane industry

Corporate Communications Staff Explores the World

March 2022

Mass Media Relations Team, Corporate Communications DepartmentKazuaki Asada

Joined Sumitomo Corporation in 2019. Had been working in the Publications Team and was in charge of creating the content and running the corporate website, Facebook account and others until October 2020. Since November of the same year, as a member of the Mass Media Relations Team, has been supporting the Transportation & Construction Systems Business Unit and the Mineral Resources, Energy, Chemical & Electronics Business Unit as well as the operations under Chief Financial Officer such as finance, accounting, and risk management, and the Asia & Oceania Region. Loves sweets enough to eat chocolates and cookies as snacks when having a drink. Since joining the company, has gained weight as a result of eating sweets during the breaktime. Out of a sense of crisis, announced the intention to go on a diet three years ago. Has been recently searching for hard pudding.

Tanegashima is located in the southwestern part of Kagoshima Prefecture and widely known as the place through which firearms were introduced to Japan. In the southeastern part of the island, the Japan Aerospace Exploration Agency (JAXA) has its Tanegashima Space Center, which is a destination for many people who want to see the launch of a rocket. On this island with a mild climate, the major industry is farming, in particular sugarcane farming.

Shinko Sugar Mill, a Sumitomo Corporation Group company, manufacturers sugar by using sugarcane grown across Tanegashima. This sugar mill was founded in 1964 and Sumitomo Corporation had a stake in it in 1980. I visited the island early January, in the middle of the harvest season for the plant. In the following I will introduce the manufacturing process of sugar, which we consume almost every day, the challenges faced by the local sugarcane industry, and the measures implemented by Shinko Sugar Mill to meet the challenges.

Long way for sugarcane to be processed into sugar

Sugarcane is a plant belonging to the rice family and grows in tropical and subtropical regions. In Japanese language, it is called "satokibi " and "kansha", in Okinawa it is known as uji and in Tanegashima as "ogi". Many Japanese people would associate sugarcane with Okinawa. Except for some areas in Shikoku, where the plant is grown, Tanegashima is the northern limit for the growth of sugarcane. Indeed, in Japan, sugarcane is widely grown on the Nansei Islands, including Okinawa. Although we tend to think that sugarcane is grown under the blue sky and against the blue ocean, it is harvested in the cold season, specifically during December to around April.

- Snippet: Origin of "Ogi"

It is said that people in Tanegashima began to call sugarcane "ogi" (literally, fan) because immediately before being harvested, the leaves of matured sugarcane look like a fan. (But there are various other opinions about this.)

As the only sugar factory located in Tanegashima, Shinko Sugar Mill purchases as much as about 150,000 tons/year of sugarcane harvested on the island from local farmers to manufacture and sell "unrefined sugar", which is crystalized sucrose made by boiling down the juice of sugarcane. The light brown colored large granules are also called "raw sugar." "Refined sugar," which is white-colored and dry, is made by separating minerals and other components from the raw sugar and is available at supermarkets.

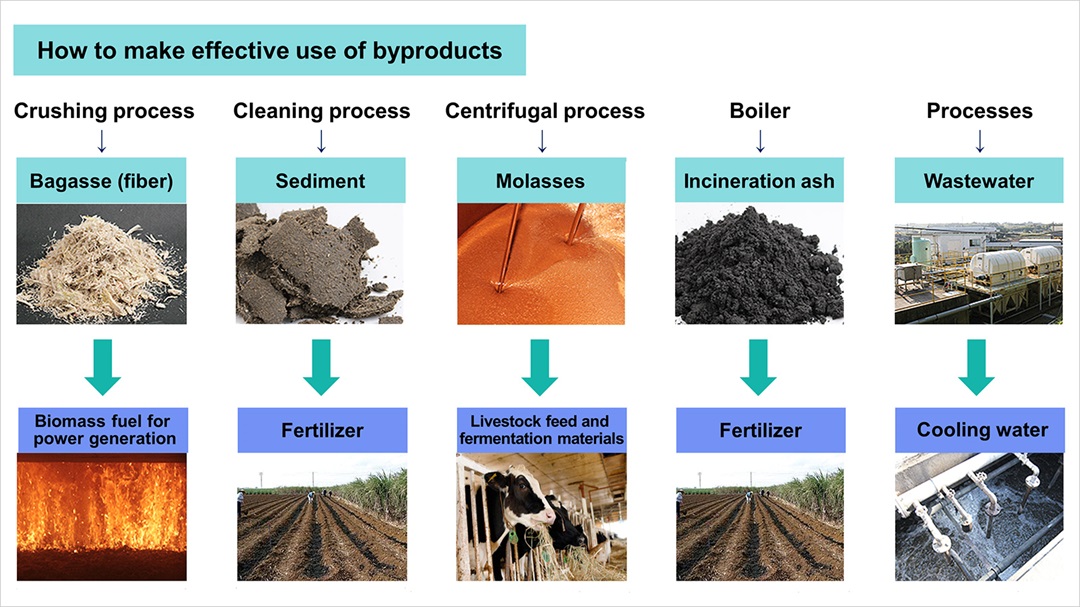

Now let us look at the raw sugar manufacturing process. It is roughly divided into the following five processes: (1) crushing process, (2) cleaning process, (3) evaporation process, (4) crystallization process and (5) centrifugal process.

(1)Crushing process

Sugarcane stalks are first of all crushed into fine fibers. Then the juice is squeezed from the fibers by a roller presser. Sugarcane can withstand the strong winds of the island and the stalks contain a lot of fiber. After the stalks are crushed and the juice is squeezed out, the residue is used as a byproduct called "bagasse." Specifically, it is used as fuel for boilers installed within the sugar factory for so-called "biomass power generation." Surprisingly, all the electricity used at the factory is derived from the bagasse fuel. Moreover, surplus bagasse is used as a "soft carpet" to cover the floor of local cattle barns, which is said to be good for the growth of the cattle.

(2)Cleaning process

In this process, impurities are removed from the sugarcane juice. The juice is heated to about 100 degrees Celsius and mixed with slaked lime in the settlement tank to be separated into "clean supernatant liquid" and the byproduct called "filter cake," which is an aggregate of impurities. The filter cake is sold as a material for fertilizer and also marketed as a special fertilizer after being mixed with incineration ash generated in bagasse power generation. The fertilizers made from the impurities are used to grow sugarcanes, contributing to increasing the yield.

(3)Evaporation process

The clean supernatant liquid is then forwarded to an evaporator to be boiled down into sticky brown syrup.

(4)Crystallization process

In this process, the liquid syrup is transported to the vacuum crystallizer to be evaporated and crystallized around small sugar granules to form large granules. In this stage, the granules and sticky liquid known as "molasses" are mixed, and this mix is called "shiroshita", which the author was specially permitted to try, and it tasted like brown sugar.

(5)Centrifugal process

The shiroshita which was made in the crystallization process is separated into the crystals of raw sugar and "molasses" by a centrifugal machine in this final process. The separated molasses is used as livestock feed and also as a fermentation material used in the manufacture of alcohol, umami seasonings and yeast.

The completed raw sugar is shipped from the port of Shimama located in the southwestern part of Tanegashima to Osaka and processed into Cup- branded refined sugar at the factory of Nissin Sugar(Renamed to WELLNEO SUGAR in October 2024), a Sumitomo Corporation Group company, to be sold across Japan.

Sugarcane is thus made into sugar through multiple processes. As some of you have already noticed, the byproducts generated in each of the processes are effectively used mainly on the island with no waste, making the local sugar factory a "zero-emission" facility.

Increase the revenues of farmers and save the sugarcane industry

The sugarcane industry in Tanegashima delivers sugar, which is an indispensable ingredient for food products. However, since 2010, the local sugarcane production has been decreasing and posing a challenge. It is due to a decrease in the cultivated acreage following the aging of farmers. The number of sugarcane farmers decreased by about 40% from 2,398 in 2010 to 1,383 in 2020, with the harvested acreage decreasing from 2,749 to 2,176 hectares and the production dropping from about 200,000 tons to 125,000 tons. Shinko Sugar Mill, being worried about the continued shrinkage of the sugarcane industry, started to implement measures to increase farmers' revenues and expand the cultivated acreage.

As one of the measures, the company is cooperating with the National Agriculture and Food Research Organization (NARO) in research to develop a new sugarcane variety named "harunoogi," which has a longer root and contains more fiber than the traditional variety, and therefore is more resistant to strong winds and typhoons. Moreover, harunoogi has a greater number of stalks, which means a higher yield per area and an increase in farmers' revenues. From fiscal year 2022, full-scale cultivation of this new variety will be started on the island.

Moreover, Shinko Sugar Mill is increasing labor saving by introducing more machines and increasing work efficiency. In addition to cooperating with the local government and excellent sugarcane producers for farmland consolidation, it also aims to support new entrants to sugarcane farming.

Aiming to develop resource circulation on the island through cooperation between agricultural and livestock farmers

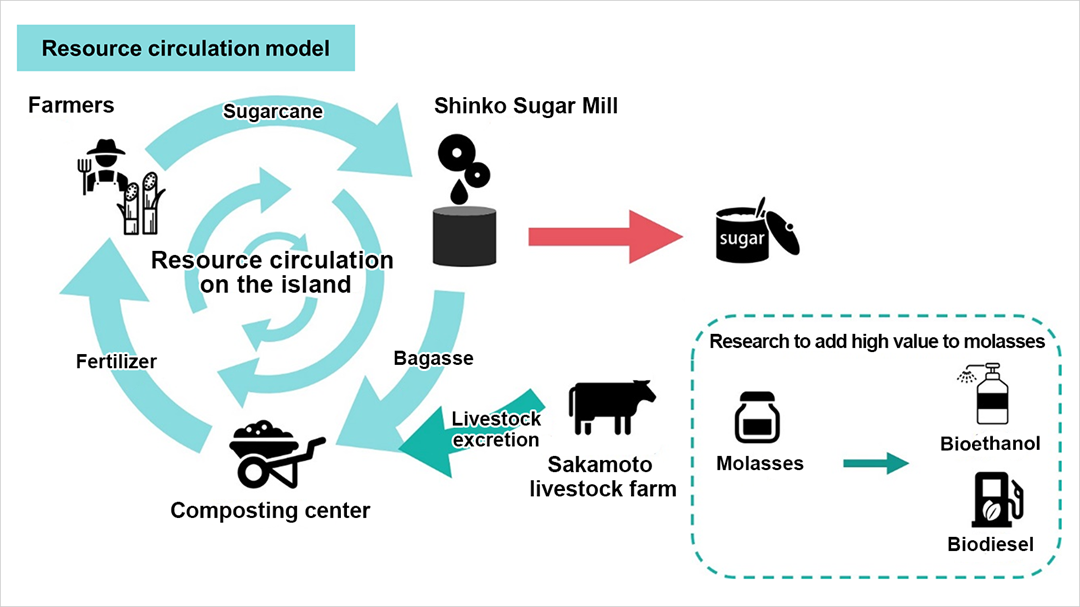

Shinko Sugar Mill has long been implementing zero-emission measures and has recently also started to work on the building of a resource circulation model on the island. In 2014, it participated in the "Smart-Eco Island Tanegashima project" and began conducting research to develop an efficient production system/method for the entire process from sugarcane farming to processing at the sugar factory jointly with Associate Professor Kikuchi at The University of Tokyo. Moreover, in 2020, the project implemented by the organizations engaged in the "Smart-Eco Island Tanegashima project to form an eco-system research base for resource circulation and local innovation" was adopted by the Japan Science and Technology Agency (JST) as one of the projects for the Agency's "COI-NEXT Nurturing (Co-Creation Area)" program.

Shinko Sugar Mill also started the manufacture of fertilizer through cooperation with both agricultural and livestock farmers. The company has been making use of the bagasse generated in its sugar production process as boiler fuel at its facilities and supplying the surplus bagasse to livestock farmers as a "soft carpet" for their cattle barns. However, about 5,000 tons of bagasse is left unused per year. Also, the new sugarcane variety of "harunoogi" contains 20% more fiber compared with the traditional variety, and therefore, the amount of surplus bagasse will increase following the full-scale use of the new variety. In order to make use of the increasing surplus, Shinko Sugar Mill formed a partnership with the "Sakamoto livestock farm", the largest of the kind in Tanegashima. At the livestock farm, about 550 milk cows are raised, and the farm faced challenges regarding the treatment of livestock excretion. Traditionally, the excretion was pooled within the farm to be supplied as fertilizer to local agricultural farmers. However, it has recently become difficult to use the excretion as it is, due to the odor and concerns over the pollution of underground water. In response, the farm mixes it with imported wooden pellets for composting, but this imposes an extra cost on the farmer to purchase the imported pellets.

The two parties, each facing their respective problems, have agreed to cooperate mutually to mix the bagasse and the excretion for composting and to sell the fertilizer to local farmers at reasonable prices. Agricultural fertilizer needs to be delivered by ship to the island and is costly, so local farmers have been reducing the use of fertilizer for cost reduction. However, the fertilizer supplied by the Sakamoto livestock farm is sold at a unit price that is less than one-third that of the fertilizer purchased from outside the island, because Shinko Sugar Mill supplies the bagasse as a material for the fertilizer in a stable manner. It is reported that some sugarcane farmers increased their yield by about 1.5 times by using fertilizer, and if more farmers use the cheap fertilizer, they will be able to increase their revenues and Shinko Sugar Mill will be able to use more bagasse as a material for the fertilizer. It is indeed an initiative intended for a circular economy.

In addition, Shinko Sugar Mill is considering making even more effective use of local resources on the island and conducting research to manufacture "bioethanol" and "biodiesel" by using the byproduct (molasses). If this plan is materialized, the company will have a new revenue source, and demand for fossil fuel-derived chemicals and fuels that need to be supplied from outside the island will diminish, which in turn may contribute to making Tanegashima carbon neutral.

Creating the comprehensive sugarcane industry for growth with the island community

Shinko Sugar Mill aims to achieve coprosperity with the island community by supporting the local sugarcane industry through support to farmers and cooperation to the development of new sugarcane varieties, in addition to supplying sugar in a stable manner as its business. The initiatives of the company are contributing to the transformation of the sugarcane industry, which used to depend solely on sugar making, to a new comprehensive industry. The future activities of the company are worth attention.

Contributing to Tanegashima by developing a circular economy

Hiroyuki Maeda, President of Shinko Sugar Mill

There are sugar factories that are generating power from bagasse for the operation of their facilities across the world, and our company is just one of these factories. We are thus not doing something very unique but may be able to expand resource circulation by making more effective use of molasses and reusing the increasing surplus bagasse. We will work to build a circular economy to contribute more to local communities.

(Extra information) Kibi-zato sugar popular for its natural taste

Nissin Sugar(Renamed to WELLNEO SUGAR in October 2024), a Sumitomo Corporation Group company, also sells "Kibi-zato sugar" products, which have natural flavor of sugarcane. The author was given the Kibi-zato sugar as a souvenir when visiting the factory and used the sugar to make a simmered dish called "Chikuzen-ni." The sugar was indeed a great option for a typical Japanese simmered dish, as I had heard. Compared with general sugar, the Kibi-zato sugar had mild flavor, and I could not stop eating the Chikuzen-ni made with the sugar. At the Nissin Sugar(Renamed to WELLNEO SUGAR in October 2024) website, where the company introduces cooking recipes, I found a recipe for a "chewy Italian pudding," and I plan to try making it. Please visit the website to enjoy making tasteful dishes by using the Kibi-zato sugar.

Keyword

- Lifestyle Business Group

- Japan

- Food Products