Aug. 07, 2023

Sumitomo Corporation creates strategic partnership to commercialize production of bioethanol from woody biomass

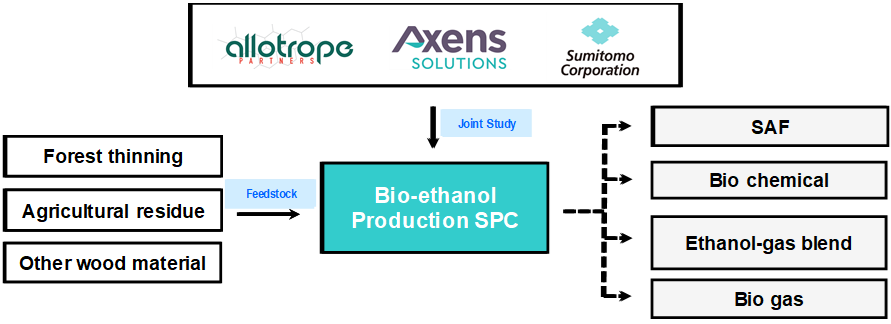

Signing of agreement between Sumitomo Corporation of Americas and two partners for a joint study

Sumitomo Corporation, through its wholly owned subsidiary Sumitomo Corporation of Americas, has signed an agreement with Axens North America, a bioethanol technology provider, and Allotrope Partners, a U.S. clean energy advisory and investment firm, for a joint project to study commercial production of bioethanol derived from woody biomass in the State of California.

Bioethanol at the center of attention amid a global movement toward carbon neutrality

Bioethanol is currently gaining notorietyon a global scale amongst countries striving for carbon neutrality as a renewable energy resource and as a feedstock for biofuels such as sustainable aviation fuel (SAF)*1 and bio-chemicals with less environmental impact. Cellulosic bioethanol made from woody biomass is low in carbon intensity*2 when compared to ethanol produced from different feedstocks and has the potential to scale sustainably.

Producing bioethanol directly from woody biomass

The objective of the project is to produce bioethanol directly from woody biomass. The feedstock is anticipated to be locally-sourced forest thinning materials and agricultural residues found in California, with the intent to produce about 60,000 tons of bioethanol annually. The ethanol produced at the plant is will to be used primarily for the production of SAF and bio-chemicals, both of which continue to grow in demand. As an additional benefit, the feedstock of this project will utilize material from forest thinning activities to reduce the serious risk of forest fires.

The United States set a target to replace all aviation fuels with SAF by 2050. To meet the increasing demand for bioethanol in the country, Sumitomo Corporation Group aims to ensure stable supply of bioethanol through this project. The Group is also planning to study the possibility of carbon dioxide capture and utilization (CCU)*3 using carbon-neutral CO2 generated collaterally during bioethanol production as well as effective utilization of residues from the fermentation process to produce biogas.

Overview of the project

Initiatives of Sumitomo Corporation's Biomass Energy & Materials Department

The mission of the Energy Innovation Initiative (EII), an organization established within Sumitomo Corporation in April 2021, is to create new businesses that contribute to establishing sustainable energy cycles and achieving decarbonization. The Biomass Energy & Materials Department, the unit of the organization in charge of this project, brings together knowledge and skills acquired across Sumitomo Corporation Group through a wide spectrum of projects to develop bioenergy in solid, liquid and gaseous forms. In February 2023, the department started a joint study with Nippon Paper Industries Co., Ltd. and Green Earth Institute Co., Ltd. for Japan's first commercial production of cellulosic bioethanol from woody biomass and its development into bio-chemical products. By further promoting bioenergy-related projects, the department will continue to play a major role in solving two of the key social issues identified and addressed by Sumitomo Corporation—Mitigation of climate change and Circular economy—and realizing a carbon neutral society.

- Sustainable aviation fuel (SAF): a sustainable aviation fuel that emits significantly less CO2 than conventional fuels throughout its life cycle, from production and collection of feedstocks to manufacturing and combustion of the fuel, and that can be used with existing infrastructure without modification

- Carbon intensity: a measure of CO2 emissions (g) per unit of energy supplied (MJ). The intensity decreases along with the reduction of greenhouse gas emissions from the supply chain.

- Carbon dioxide capture and utilization (CCU): the process of separating and capturing CO2 and effectively utilizing it as a resource in crop production and the manufacture of chemical products