Oct. 18, 2023

Launching a Pilot Project to Make Biofuel and Biochemicals out of Rice HusksBuilding a business model for commercialization of local-production-for-local-consumption-based decarbonization in Tainai City, Niigata Prefecture with a view to global expansion

Sumitomo Corporation together with Sony Group Corporation and Sony Intellectual Property Services Corporation (hereinafter, collectively “Sony”), will launch a pilot project for using rice husks to make a fossil fuel substitute as well as to manufacture silica and activated charcoal.

Large volumes of rice husks are generated as waste products around the world. By using them to produce bioenergy with substantially lower CO2 emissions as well as silica and activated charcoal, biochemicals that can be sold at high unit prices, Sumitomo Corporation aims to contribute to decarbonization in a way that is economically rational. Under this initiative, with support from Tainai City in Niigata Prefecture and the local Japan Agricultural Co-operative (JA), technologies and applications will be developed for the establishment of a new business model for decarbonization based on local production for local consumption, with a view to expanding it across Japan and the wider world.

The amount of rice husks generated in the milling process totals 100 million tons or more on a worldwide basis and around 2 million tons in Japan alone. As incineration of rice husks is prohibited in a number of regions due to the smoke and odor produced, various kinds of proposals have recently been made for their effective use. As of today, however, vast amounts of rice husks are still being disposed of as general waste, with the outdoor incineration and dumping into rivers of these husks being a source of environmental pollution.

In the pilot project based in Tainai City, Sumitomo Corporation will work to develop the following technologies and applications:

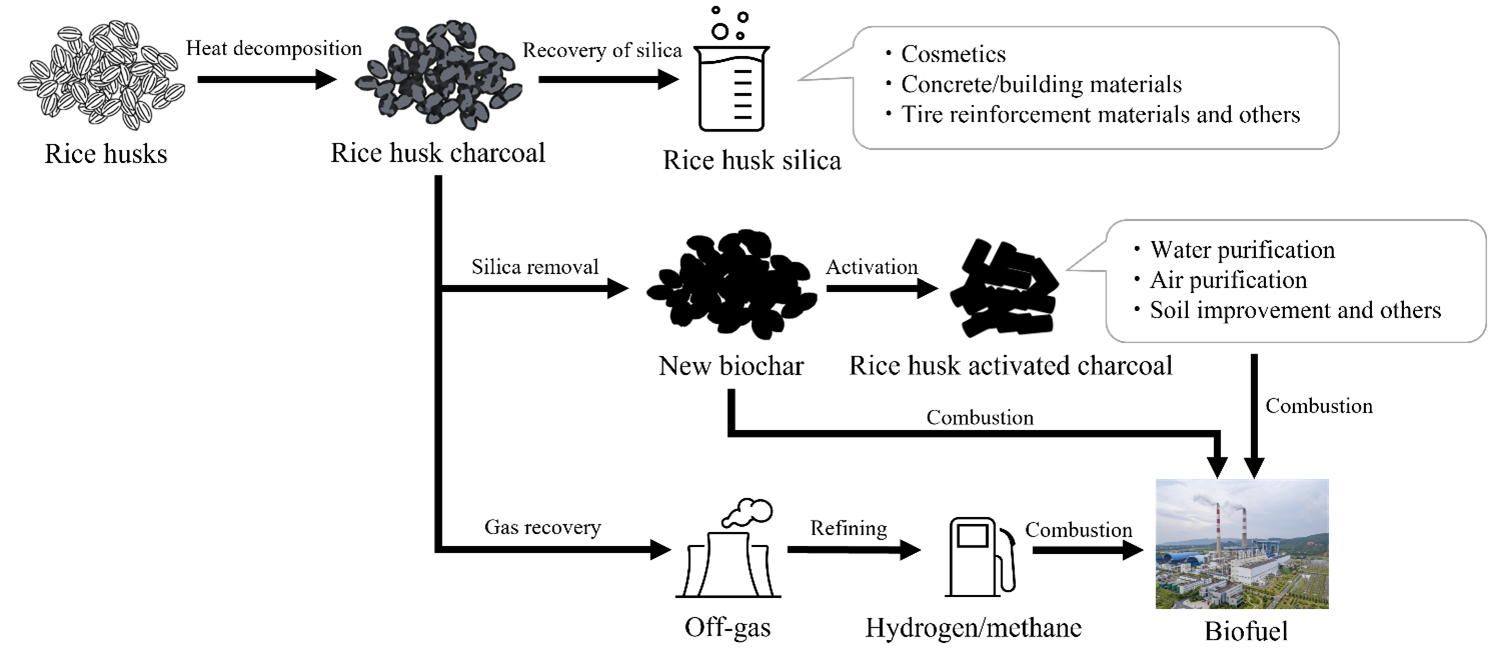

(1)Technology to thermally decompose and carbonize rice husks generated and collected in Tainai City for the manufacture of rice husk charcoal (*1)

(2)Application of rice husk silica (*2) extracted from the rice husk charcoal as an environment-friendly high value-added material

(3)Process to turn silica-extracted rice husk charcoal into biochar, and technology and application for the manufacture and effective use of rice husk activated charcoal (*3)

(4)Technology to utilize the off-gas (*4) generated in the rice husk charcoal manufacturing process as renewable energy

Sumitomo Corporation aims to build a business model that makes decarbonization economically rational through the comprehensive development of technologies and applications as described above. In recognition of its significance, the initiative will be subsidized under the Technology Development and Demonstration Project for Regional Symbiosis and Cross-Sectoral Carbon Neutrality, for which the Japanese Ministry of the Environment opened a second call for applications for fiscal 2023 with the aim of supporting projects that are intended to generate both a substantial reduction in CO2 emissions and regional revitalization.

For the rice husk activated charcoal as described in (*3) above, Sumitomo Corporation will collaborate with Sony, which is fostering its own Triporous (*5) rice husk-derived porous carbon material business, toward the establishment of the required manufacturing technology as well as for application development.

| (*1)Rice husk charcoal | : | Carbonized rice husks | |

| (*2)Rice husk silica | : | Fine silica particles derived from rice husk incineration ash | |

| (*3)Rice husk activated charcoal | : | Carbon-based porous material made by chemically or physically treating rice husk charcoal to increase its substance adsorption efficiency | |

| (*4)Off-gas | : | Combustible gas generated in the carbonization process | |

| (*5)Triporous | : | This porous carbon material is made from rice husks, which are generated in a total worldwide amount of 100 million tons per year. Because of its patented fine structure, Triporous is expected to be used for a range of applications including water and air purification. Being produced from a surplus biomass material, Triporous also contributes to the realization of an environment-friendly recycling-based economy as well as to the reduction of air pollutants and greenhouse gas emissions from the incineration and landfilling of biomass waste. |

| (*1)Rice husk charcoal | : | Carbonized rice husks | |

| (*2)Rice husk silica | : | Fine silica particles derived from rice husk incineration ash | |

| (*3)Rice husk activated charcoal | : | Carbon-based porous material made by chemically or physically treating rice husk charcoal to increase its substance adsorption efficiency | |

| (*4)Off-gas | : | Combustible gas generated in the carbonization process | |

| (*5)Triporous | : | This porous carbon material is made from rice husks, which are generated in a total worldwide amount of 100 million tons per year. Because of its patented fine structure, Triporous is expected to be used for a range of applications including water and air purification. Being produced from a surplus biomass material, Triporous also contributes to the realization of an environment-friendly recycling-based economy as well as to the reduction of air pollutants and greenhouse gas emissions from the incineration and landfilling of biomass waste. |

Through the demonstration experiment, Sumitomo Corporation aims to establish a low-CO2 biochemical (*6) manufacturing process and a technology to make effective use of the off-gas generated as energy. Furthermore, on the premise that a market for environment-friendly high value-added biochemical products with proven economic rationality is created, Sumitomo Corporation will launch a business to make effective use of the 500 tons of rice husks generated in Tainai City in 2026, with an eye to expanding the business across Japan and beyond sometime around 2030. Based on its achievements made in various business domains as an integrated trading company—particularly the expertise gained through its silica and various other inorganic materials-related businesses—and a proven track record of off-gas development, Sumitomo Corporation will promote the marketing and trading of the developed biochemical products following their commercialization. For the highly environment-conscious cosmetics industry, for example, in-house teams engaging in the cosmetics materials business will contribute to promoting sales of rice husk silica to both domestic and overseas manufacturers of renowned cosmetic brand products.

| (*6) | For rice husk silica, CO2 emissions will be reduced by 50% relative to conventional silica made from minerals. For biochar and off-gas and for rice husk activated charcoal, respectively, specifications that meet various biomass fuel standards and those that meet the standards set by the Japan Water Works Association will be pursued. As a result, for the entire manufacturing process, CO2 emissions will be reduced by 2.3 tons for every ton of rice husks used. |

| (*6) | For rice husk silica, CO2 emissions will be reduced by 50% relative to conventional silica made from minerals. For biochar and off-gas and for rice husk activated charcoal, respectively, specifications that meet various biomass fuel standards and those that meet the standards set by the Japan Water Works Association will be pursued. As a result, for the entire manufacturing process, CO2 emissions will be reduced by 2.3 tons for every ton of rice husks used. |

Sumitomo Corporation aims for carbon neutrality by 2050. As such, it is taking on the challenge of realizing a sustainable energy cycle while also shifting toward recycling-oriented and resource-saving technologies and products in order to build a supply chain that contributes to the creation of a circular economy, thereby achieving harmony with the global environment. At the same time, Sumitomo Corporation will contribute to the development of local industries and human resources in regions where it operates with a view to the development of local communities and local economies. The idea for this initiative was born through the “0→1Challenge” intrapreneurship program. Sumitomo Corporation will promote the company-wide reform of its business model and create new value by leveraging the individuality and creativity of each employee while responding to significant changes occurring in the world.

[0→1Challenge]

0→1 Challenge is an intrapreneurship program launched in fiscal year 2018. The program is intended to foster the commercialization of business ideas proposed by on-site employees, and all Sumitomo Corporation Group employees across the globe are invited to propose their ideas for commercialization through this program, regardless of affiliation, job rank or years of service.

The program was launched based on the concept of creating a next-generation business (“one/1”) from an unprecedentedly new idea (“zero/0”). By taking on the challenge of commercializing their own ideas, employees with passion can help their company reform its existing businesses while also broadly inspiring their fellow employees and encouraging them to think in new ways. The program is therefore implemented by attributing importance also to the development of employees and the nurturing of a culture of embracing challenges, and is not simply focused on increasing the rate of successful commercialization of proposed ideas. For the five-year period from fiscal 2018 to fiscal 2022, a total of roughly 1,000 ideas were proposed under the program, and activities have been conducted for the commercialization of 11 ideas to date.

Proposer of the idea for the initiative: Naoya Ito, Green Chemical Business Development Dept.

I hit upon the idea after harvesting rice that I had grown myself in a rented paddy field. Becoming interested in the rice husks generated in the process of milling the grains, I undertook an investigation into how they were disposed of. When I learned that the inappropriate disposal of rice husks was causing environmental pollution and damaging people’s health, I then wanted to do something to deal with the problem, as a citizen of Japan, where rice is consumed as a major staple. I also wanted to ensure that we would be able to pass down our beautiful rural landscapes and delectable rice to younger generations so that my children can also enjoy these blessings when they grow up. So I made a proposal about rice husks through the 0→1 Challenge program.

Initially, I was focusing solely on silica. However, as we made progress in the project with the participation of Sony as a business partner, the scope began to expand to include activated charcoal, off-gas and biochar. I am now excited about the potential of the business, which can become one that truly deserves to share the reputation that the company enjoys as an integrated trading company. It is almost three years since the launch of this challenging project. I occasionally get frustrated when progress becomes bogged down in some detail or other, but I intend to work patiently until we can harvest its benefits, which I hope will be as bountiful as the harvest of Koshihikari rice that grows abundantly in Tainai City.

(Major “0→1 Challenge” projects implemented to date)

Capital and Business Tie-up with The Chain Museum to Operate Business in ArtLaunching Proof of Concept Project of “kaigo FIKA”, Caregiver Retention Support Service

Launching Pilot Program for Matching Platform for Licensing Business (In Japanese only)

Trial of “Any Wear, Anywhere” Clothing Share Service for Overseas Visitors

Launching Pilot Program for the “Life Wash” laundry service (In Japanese only)