- TOP

- Enriching+TOP

- Continuing to provide the best quality with masterful techniques in the rapidly changing automotive industry

2023.10.1

Business

Continuing to provide the best quality with masterful techniques in the rapidly changing automotive industry

This content was originally published in October 2022.

- Matching aspirations of two companies leads to M&A

- Extensive Proposal ability based on experience and know-how

- Transcending cultural and language barriers to satisfy market needs with best-quality products

- Renovating casting equipment at the headquarters plant to reduce environmental impact

- Evolving manufacturing to shape the future of the Sumitomo Corporation Group

Matching aspirations of two companies leads to M&A

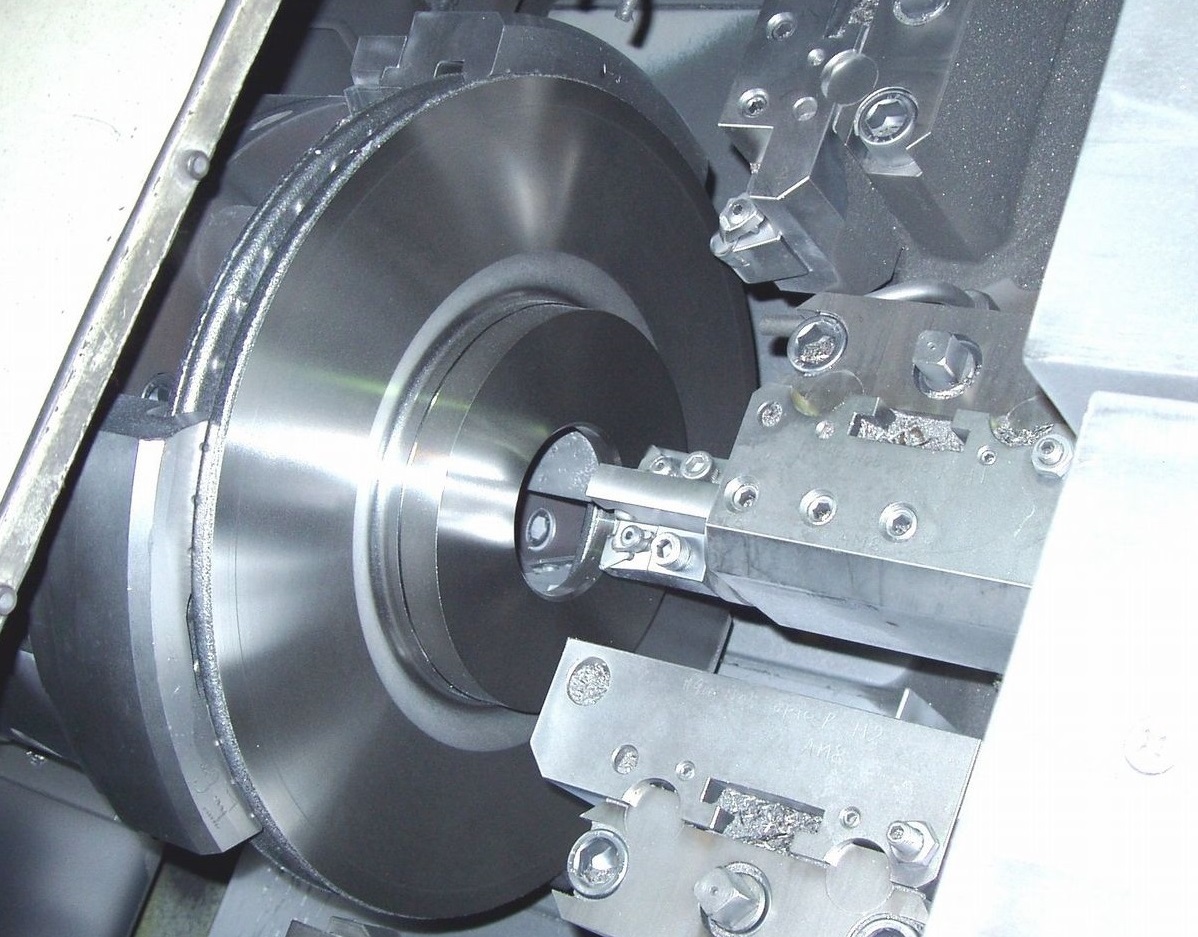

Pouring iron melted at the high temperature of 1,500 degrees Celsius into a sand mold, cooling it for solidification, and finishing it as a high-precision product with machining. It was 2004 when Sumitomo Corporation became fully involved in the casting and processing of automotive parts in partnership with Kiriu Corporation.

In July of the same year, Kiriu Corporation, based in Ashikaga City in Tochigi Prefecture, became affiliated with Sumitomo Corporation. Founded in 1906, Kiriu is a long-established manufacturer. It initially manufactured textile preparatory machines before starting to manufacture automotive parts in the 1960s. While many auto parts manufacturers focus on particular manufacturing processes, Kiriu is one of the few manufacturers that carries out not only product development and design as well as casting and processing, but also makes machining facilities in-house. Additionally, based on its unique production model called "Ikki Seisan" (*1) (literally, integrated production) , Kiriu efficiently manufactures parts, primarily high-quality, high-precision brake discs and brake drums, and supplies them to numerous carmakers. Currently, Kiriu's parts can be found in one out of every 10 cars in the world.

Sumitomo Corporation was taking on a new challenge based on a new business model of investment outside the trading business. Kiriu was aiming to expand its business overseas. The aspirations of the two companies matched, resulting in the M&A in 2004. Over the 14 years since then, Sumitomo Corporation, as the 100% shareholder, has supported Kiriu's business.

*1 Ikki Seisan: An effective integrated production system that eliminates waste in processes from development/design to production and shipment, including in-house manufacturing of molds and facilities

Extensive Proposal ability based on experience and know-how

The greatest strength of Kiriu is its ability to provide carmakers with proposals based on its unique design and development capability, which is one of the best in the industry. With the advances in electric vehicle (EV) development, the market share of conventional gasoline engine vehicles is likely to gradually decline. The three key functional operations of automobiles will nevertheless continue to be "run," "turn" and "stop."

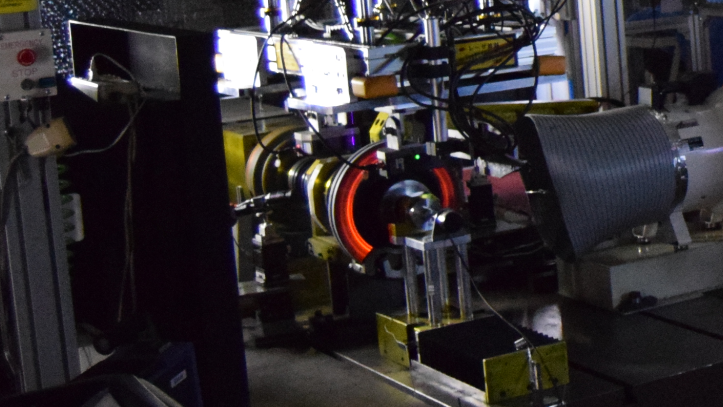

In particular, brakes, which are responsible for the function of stopping safely, will continue to be indispensable to automobiles. To achieve a safe mobility society against the background of a rapidly changing automotive industry, carmakers demand very high quality standards for brakes. Kiriu has continued to satisfy the demand for high quality standards for many years by using experimental technologies, including cutting-edge simulation technology, 3D modeling and computational fluid dynamics (CFD), along with advanced proprietary casting and machining technologies. Its unrivaled technology to reduce the sound and movement of a car body when a brake is applied has over the years been Kiriu's competitive edge in manufacturing high-quality parts. Based on its experience and technologies, Kiriu, using its development capability, has offered the accurate proposals to carmakers, earning it trust from customers and allowing the company to outstrip its competitors. Kiriu will continue to respond to the ever-changing car manufacturing industry with its advanced proposals and high-level technical quality.

Transcending cultural and language barriers to satisfy market needs with best-quality products

However high technology a Japanese company has, it must standardize its know-how and develop an international workforce to assert itself outside Japan. Initially, in 2004, Kiriu had three domestic sites and three overseas sites. Over the following 14 years, it increased its sites to four in Japan and nine outside Japan, almost doubling its sales.

In operating business outside Japan, Kiriu's biggest challenge was to maintain the Kiriu quality despite the difficulties arising in relation to cultural and language barriers. There were also many other issues, such as the different political and economic situations of different countries as well as different legal systems, customs and responses to demand trends. By combining Kiriu's high-level technologies and expertise in manufacturing with Sumitomo Corporation's integrated corporate strength based on its wealth of knowledge about doing business overseas, Kiriu has improved its workplace environment to the extent that workers from all kinds of different backgrounds can fulfill their potential and smoothly promote the company's business outside Japan.

Kiriu has also diversified its customer base. Together with Sumitomo Corporation, it is increasing transactions with foreign carmakers in addition to those from Japan. In recent years, it has been cooperating with China-based Fujiwa Machinery Industry, in which Sumitomo Corporation has a 45% stake.

Renovating casting equipment at the headquarters plant to reduce environmental impact

In March 2020, Kiriu decided to renovate its casting equipment at the plant located at the headquarters in Ashikaga in order to minimize parts supply risks associated with equipment failure, as well as to improve productivity through automating weighing and handling processes and enhance cost competitiveness. Moreover, by replacing the current coke-fired blast furnace for melting iron with an electric furnace, Kiriu aims to reduce CO2 emissions by 30% compared to the conventional system (approximately 10,000 tons are equal to 0.6% of the Group's annual CO2 emissions), thereby contributing to solving social issues such as climate change and air pollution.

As the market for EVs is expected to expand in the future, EVs, which are heavier than gasoline-powered vehicles due to the on-board batteries, will be subject to more stringent fuel efficiency requirements. By developing and supplying products that meet the growing need for weight reduction, Kiriu hopes to contribute to the realization of an environmentally friendly automotive-based society.

The new state-of-the-art facilities will improve working conditions at the site, such as noise and dust, and help reduce heavy manual work and the incidence of serious accidents. Kiriu strives to create a workplace environment that is friendly to workers.

Evolving manufacturing to shape the future of the Sumitomo Corporation Group

For Sumitomo Corporation as an integrated trading and investment company, having manufacturers in its group is crucially important because it allows it to apply knowledge and technologies acquired on the front line of manufacturing to other areas.

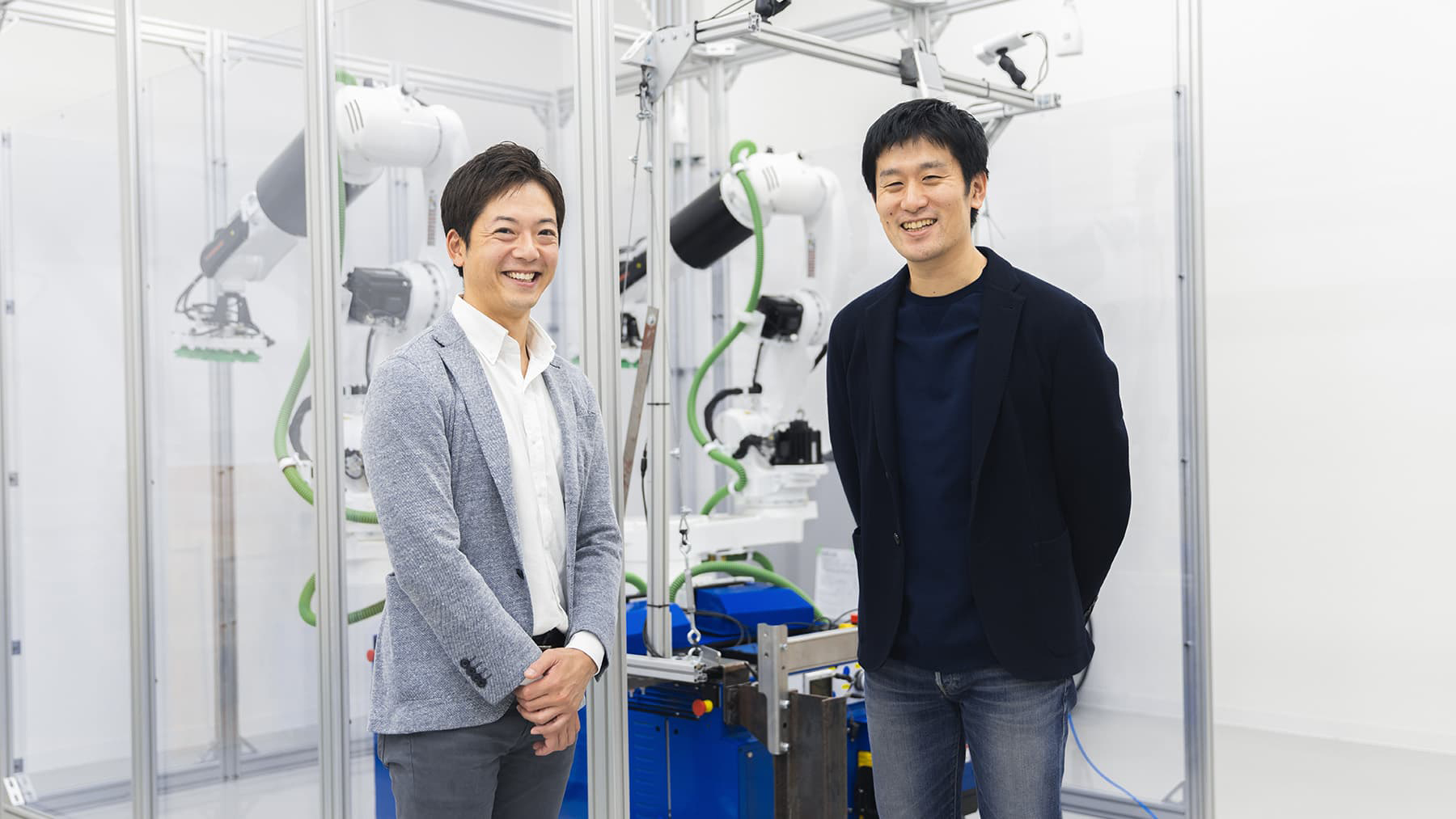

The Sumitomo Corporation Group is promoting group-wide digital transformation (DX) to further improve Kiriu’s manufacturing lines by using digital technologies, including IoT, data management and AI, and to create new business for the next generation based on the DX experience at Kiriu. The evolution of Kiriu’s manufacturing will definitely be one of the weapons in promoting DX at other manufacturers.

Together with Kiriu, Sumitomo Corporation will continue to supply high-quality products anytime, anywhere and to anyone for a safe and comfortable car-oriented society.