- TOP

- Enriching+TOP

- Flying Planes and Growing Forests: A Joint Challenge by Sumitomo Corporation, Nippon Paper Industries and JAL to Produce Domestic SAF from Tohoku

2025.10.21

Business

Flying Planes and Growing Forests: A Joint Challenge by Sumitomo Corporation, Nippon Paper Industries and JAL to Produce Domestic SAF from Tohoku

The airline industry aims to be carbon neutral (virtually zero CO2 emissions) by 2050. Sumitomo Corporation is participating in the Project Morisora manufacturing sustainable aviation fuel (SAF) from timber sourced in Japan's Tohoku region. This initiative promotes decarbonization while contributing to forest cycle and regional recovery. Today we spoke with representatives from Nippon Paper Industries and Japan Airlines (JAL), our partners in this endeavor, about its broader significance.

-

Manager, Bioethanol Business

Promotion Office,

Technical & Engineering Division,

Nippon Paper IndustriesYohei Haneo

Haneo joined the company in 2023 after working in government and IT. He has been involved in the Project Morisora since joining, coordinating the Demonstration Project for Bioethanol Production and SAF certification schemes.

-

Vice President,Domestic

SAF Promotion Task Force,

Japan Airlines

Atsushi KitaKita joined Japan Air System in 2003 (merged with JAL in 2006) and worked in Maintenance and Engineering department. He took up a position related to domestic SAF through an internal recruitment program at the end of FY2022 and has been in his current post since 2023.

-

Biomass Energy Business Unit,

Cross Industry Collaboration and

Development (CCDU) Unit (concurrent),

Sumitomo CorporationTohru Abe

Abe joined Sumitomo Corporation in 2019 after gaining experience in real estate companies and funds and was assigned to the Real Estate SBU Building Business Unit. Since 2023, he has been responsible for project management of the Project Morisora as well as decarbonization-related business development at CCDU, including geothermal for buildings.

- Used Cooking Oil and Waste Become Jet Fuel? What is SAF, the Key to Decarbonizing the Aviation Industry?

- Cross-Industry Collaboration to Produce SAF from Forest Resources

- More Than Decarbonization: Revitalizing Forest Cycles and Tohoku

- As End User, JAL Recognizes the Multifaceted Project Value in Resolving Social Issues

- Social Implementation of Domestic SAF From Tohoku: The Project Morisora Growing Together with Society

Used Cooking Oil and Waste Become Jet Fuel? What is SAF, the Key to Decarbonizing the Aviation Industry?

SAF stands for "sustainable aviation fuel" – it's essential for decarbonizing aviation and is currently drawing attention worldwide. Feedstocks include used cooking oil, municipal waste and timber. Across its life cycle, from feedstock production and procurement to manufacturing, transport and combustion, SAF can reduce CO2 emissions by about 80% compared to conventional jet fuel. However, production costs and stable feedstock supply remain challenges. Japan's Ministry of Economy, Trade and Industry (METI) has set a target of replacing 10% of fuel used by domestic airlines with SAF by 2030, and public-private initiatives are underway.

Cross-Industry Collaboration to Produce SAF from Forest Resources

Could you outline the Project Morisora?

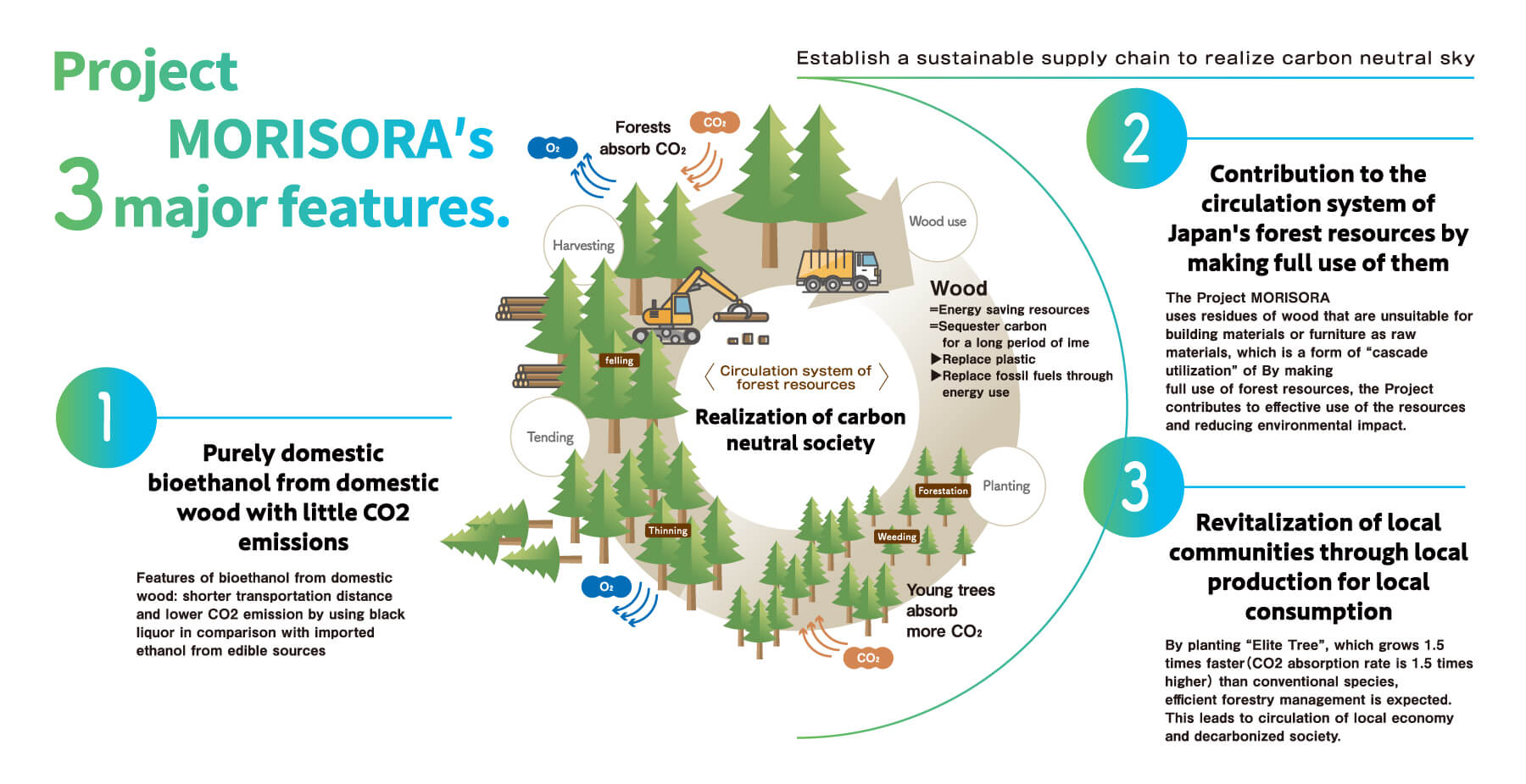

Abe The project was launched in 2023 under the slogan "From Forest to Sky: Transforming the power of forest into the power of flight" by Nippon Paper Industries, Sumitomo Corporation and the Green Earth Institute (GEI). More than two-thirds of Japan's land area is forest. Using this abundant resource, we plan to produce over 1,000 kiloliters per year of bioethanol as a SAF feedstock. Since 2024, JAL and Airbus – who will ultimately use the SAF – have also joined the project.

How did the project come about?

Haneo It started with Nippon Paper exploring new uses for wood materials as demand for paper declined. In partnership with Sumitomo Corporation, with whom we have longstanding ties in forest products like pellets and lumber, we began examining a business to produce ethanol from timber as a SAF feedstock.

Abe In 2023, Nippon Paper Industries, Sumitomo Corporation, and GEI signed an MoU (Memorandum of Understanding), and in July 2025 the three companies established the joint venture, Morisora Biorefinery. After the MoU was signed, we held face-to-face meetings once a week, and by the time the joint venture was formed two years later, we had already exceeded 100 regular meetings. Throughout, we advanced the project with a strong sense of each other’s passion and commitment. After the joint venture was launched, we visited Namie Town in Fukushima Prefecture and held workshops with residents and municipal representatives. These exchanges made us keenly aware once again of the significance of our initiative and the social responsibility it carries.

As for the roles of each company: Nippon Paper handles feedstock procurement and SAF-related certifications; GEI licenses its technology; Sumitomo Corporation supports project promotion, information gathering, marketing and sales development.

More Than Decarbonization: Revitalizing Forest Cycles and Tohoku

What makes this project distinctive?

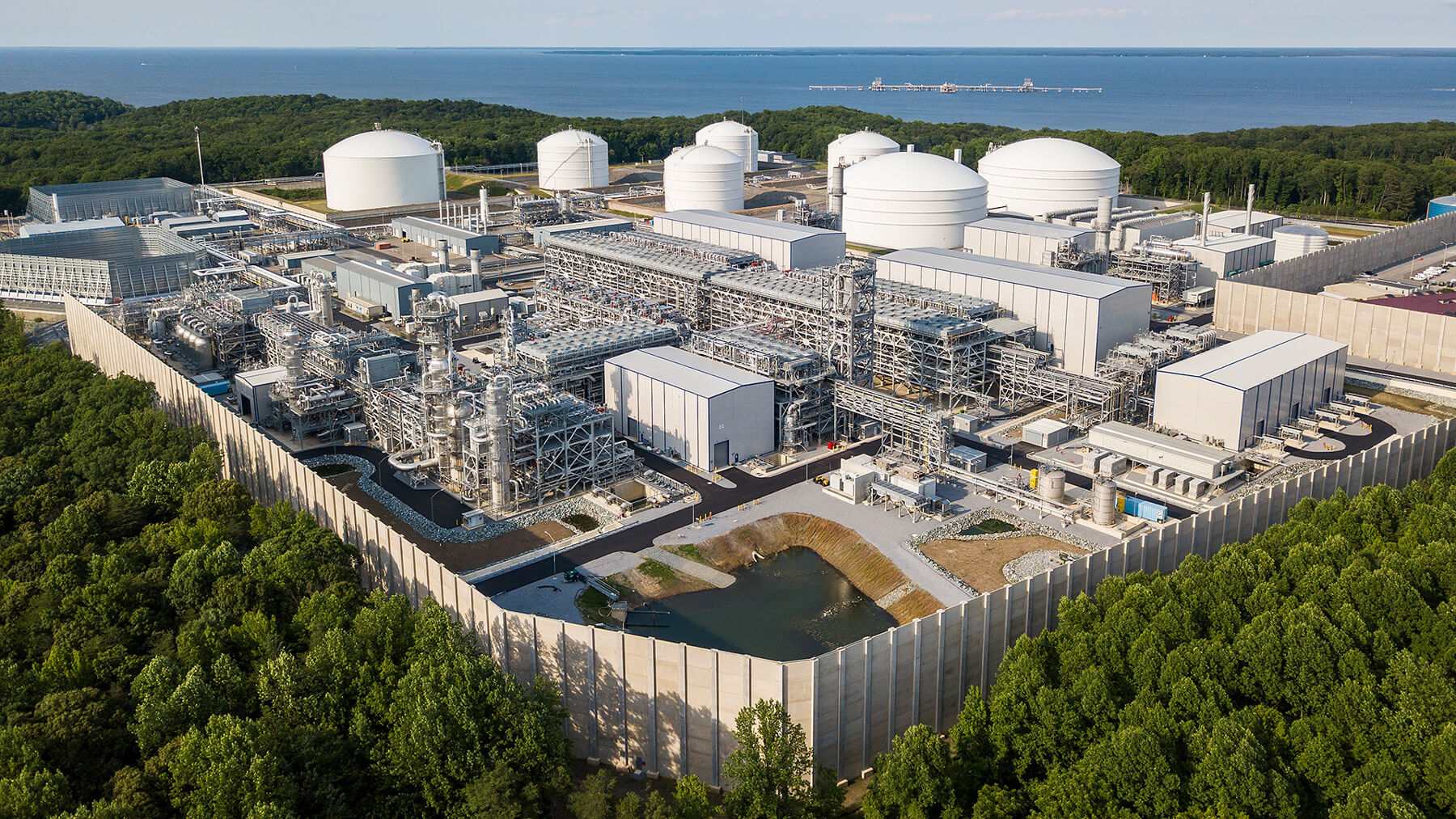

Abe As a local-production-for-local-consumption initiative relying on domestic timber, we achieve high GHG (greenhouse gas) reduction efficiency. Using imported timber would add transport costs and emissions. While many paper companies rely on cheap imports, Nippon Paper is committed to domestic wood. At the Iwanuma Mill, which will host the project, nearly all the timber used will be sourced domestically.

Haneo The project also contributes to maintaining valuable forest resources. Without timely harvesting, forests become unhealthy and degraded. Tohoku's forestry was badly hit by the Great East Japan Earthquake, and some areas remain off-limits, leaving forests untended and deteriorating. With an aging workforce, abandonment accelerates degradation. By using timber, we help restore forest circulation in the region alongside regional economic cycles as a result.

Nippon Paper's Ishinomaki Mill was damaged by the tsunami and the Iwanuma Mill was forced to suspend operations after the disaster due to damage. Launching a new business from such symbolic locations carries special meaning for revitalizing Tohoku.

Abe In addition, the project carries significant implications from the perspective of energy security. At present, Japan’s ethanol self-sufficiency rate is only around 1%, leaving the country heavily reliant on imports. This dependence exposes us to price fluctuations and supply risks. That’s why it’s so important to establish technology that can produce ethanol from domestic timber at a reasonable cost. I see this as a bold challenge with the potential to grow far beyond Japan, opening doors to international expansion and new opportunities.

As End User, JAL Recognizes the Multifaceted Project Value in Resolving Social Issues

How does JAL, as an end user, view the project's significance?

Kita SAF is our top long-term challenge. The industry has set a goal of replacing 10% of fuel with SAF by 2030, but current supplies from used cooking oil are far from sufficient. We've long been interested in wood-based SAF using Japan's rich forest resources.

Of the diverse SAF projects JAL participates in, this one stands out for its potential to help address the social challenge of creating a local-production-for-local-consumption cycle for forest resources. This perspective was strongly shaped by the severe impact sustained by the airline industry during the COVID-19 pandemic. One of JAL’s management priorities is to "expand the breadth and depth of regional relationships and connections," and reflecting on the fundamental significance of our business – namely, "transporting people and goods across Japan and around the world" – was one of the reasons we decided to take part in this project.

So, you felt the multifaceted value of this project was especially compelling?

Kita Yes, in fact, the share of SAF produced by the Project Morisora will not be very large in terms of total usage. Regardless, I believe this project is of exceptionally high value and strong social significance. Simply buying what someone else has produced is easy, but that alone will not nurture the market. From our position as a user, we feel a responsibility not just to wait passively for SAF to be completed, but to take proactive steps ourselves.

*Elite trees grow 1.5 times faster, produce less pollen and have straighter trunks than standard cedar or cypress.

Social Implementation of Domestic SAF From Tohoku: The Project Morisora Growing Together with Society

In driving this project forward, how do you intend to leverage each company’s strengths?

Haneo Nippon Paper will make use of existing facilities such as mills, as well as its extensive wood procurement network – the second largest in the industry by revenue – to help secure feedstock reliably while controlling investment costs.

When producing ethanol from wood, a key challenge is separating the lignin contained in wood. Achieving this efficiently is essential to lowering costs. In this regard, we can draw on the technology and expertise we have cultivated in paper manufacturing, particularly in the process of "how to make paper white." This enables us to carry out production efficiently. Incidentally, the separated lignin can be used as fuel, and we also make effective use of CO2 and residues generated in the manufacturing process. Together, these measures allow us to produce SAF at lower cost, with higher environmental value, and with competitive advantage.

Kita As you point out, to socially implement and popularize SAF, it must be competitive in the market. To create a product that users genuinely want, we intend to contribute our knowledge and insights as an airline, grounded in a deep understanding of the aviation market.

Abe Sumitomo Corporation will draw on its management experience and network developed through joint ventures and project operations to engage with government bodies and expand collaboration with diverse companies. In addition, we see it as our role to propel the project as a whole – connecting the strengths of each partner – by leveraging our international expertise and financial resources.

Looking ahead, what are your prospects and aspirations?

Abe First, in 2027 we will put a demonstration bioethanol plant into operation, refining technologies to raise production efficiency. Building on the knowledge accumulated there, we aim to move to a commercial plant capable of producing tens of thousands of kiloliters of bioethanol annually, thereby realizing domestically produced SAF. The challenge, of course, is controlling costs, but beyond the price tag, we also want to develop a framework where our contribution to decarbonization can be recognized and evaluated.

Haneo I have been involved in this project since joining the company, so I feel a strong determination to see it through to social implementation and, ultimately, commercialization. SAF development is a national project in which the public and private sectors work hand in hand. Precisely for this reason, we must not be swayed by short-term changes or difficulties. Instead, I want us to form a solid united front with all participating companies to push the project forward.

Kita At JAL we also want to work together with everyone to advance the social implementation of SAF. The key to wider adoption is whether people will understand its value and significance, and whether we can gain the support of our customers. At the heart of this is the ability to clearly convey why we are undertaking this project. In simple terms, it is for decarbonization, but more than that, it is a project with profound significance for our planet, and for everyone. We intend to step up our PR activities so that as many people as possible recognize this.

Abe Exactly. This initiative is not something that companies can bring to fruition on their own. Everyday choices – such as "which fuel powers the plane I’m flying in?" – can nurture the forests of Tohoku and eventually lead to the spread of domestically produced SAF. If we can engage people's interest and their actions as consumers, the Project Morisora can make major progress. Moving forward, we will work with our partner companies to deliver value across all of society.