- TOP

- Enriching+TOP

- Can Truck Loading Be Automated? Sumitomo Corporation Meets Next-Generation Robot AI for Logistics Revolution

2025.4.3

Business

Can Truck Loading Be Automated? Sumitomo Corporation Meets Next-Generation Robot AI for Logistics Revolution

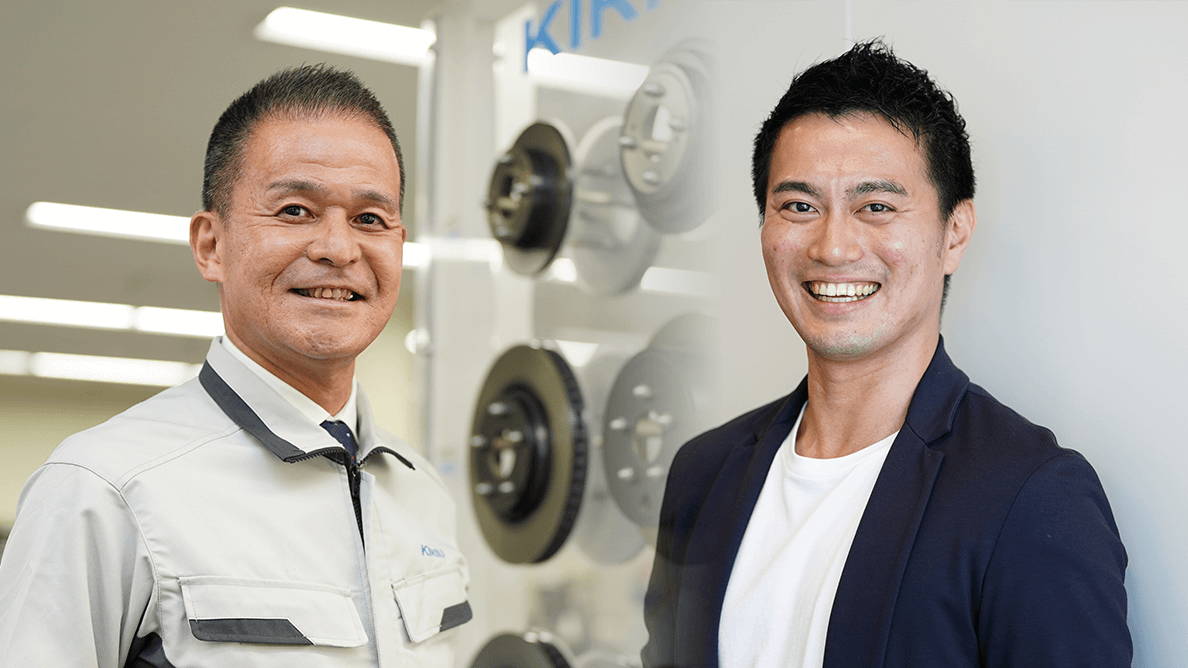

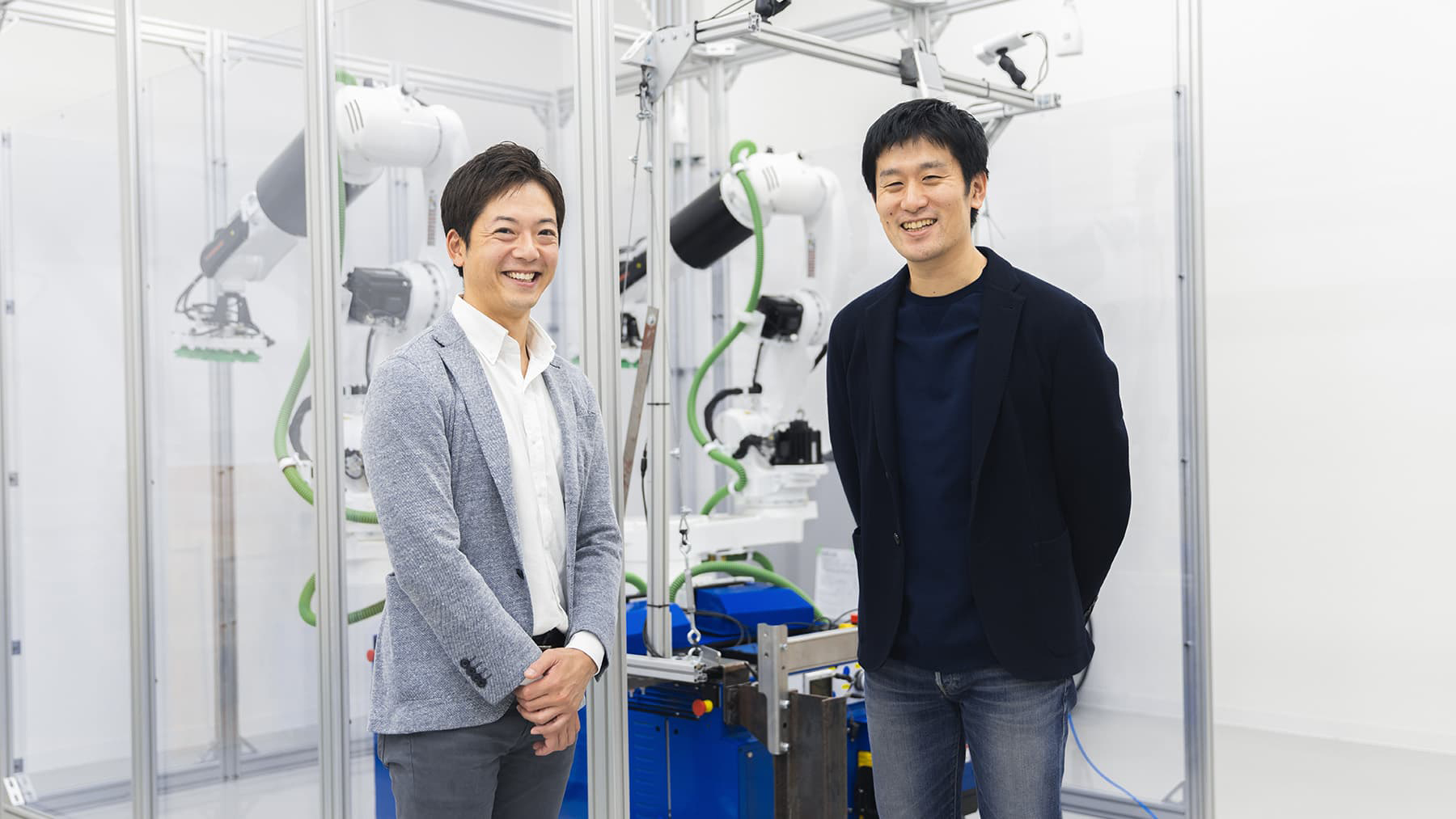

In June 2024, Sumitomo Corporation and the American unicorn company Dexterity, Inc. established the Dexterity-SC Japan joint venture. The company's primary goal is to solve Japan’s logistics challenges through the practical application of Dexterity’s next-generation robot AI. We spoke with the company’s CEO Shotaro Oyama and COO Kosuke Ichikawa about Sumitomo Corporation’s aims in entering the Robotics-as-a-Service (RaaS) business, the strengths of Dexterity’s robot AI and their robot system for cargo loading.

-

CEO, Dexterity-SC Japan

Shotaro Oyama

After joining Sumitomo Corporation as a new graduate in 2006, Shotaro was responsible for various ICT-related businesses. Following an assignment in Singapore, he engaged in venture investment operations at the New Business Investment Department, focusing on business development within the Sumitomo Group. Since Sumitomo Corporation’s investment in Dexterity in 2020, he has been in charge of business development at the company, leading to the establishment of Dexterity-SC Japan in June 2024, where he now serves as CEO.

-

COO, Dexterity-SC Japan

Kosuke Ichikawa

Kosuke joined Sumitomo Corporation in 2008 and was assigned to the Coal Department of the Mineral Resources and Energy Division. Including a two-year assignment at a mine in Bolivia, he was involved in mineral resource trading and investment operations. In 2019, he transitioned to the Automotive Group, focusing on EV and battery-related businesses. From 2022, Ichikawa supported the business launch of an EV startup to which he was seconded for two years. In June 2024, he became COO of Dexterity-SC Japan.

Next-Generation Robot AI Makes "Human-like Movement" a Reality

First, could you give us the background behind Sumitomo Corporation’s entry into the RaaS business?

OyamaThe logistics industry faces numerous challenges – including an aging driver population, labor shortages, increased cargo volume due to the expansion of e-commerce and the "2024 Problem in Logistics"* – which together have resulted in a decrease in transportation capacity and driver shortages. Sumitomo Corporation has been addressing these issues through several initiatives.

The key to solving these challenges lies in next-generation robot AI. While industrial robots have long been used in automated production lines, they were mostly limited to performing simple, repetitive tasks that were pre-programmed. However, recent advancements in AI technology, including generative AI, have enabled robots to learn from large datasets, make autonomous decisions, and accurately perform tasks such as sorting and organizing packages.

*Issues caused by new regulations that limit truck driver overtime to 960 hours per year, which took effect in April 2024, and the revised Notice of Improvement Standards, which, in turn, reduce transportation capacity and exacerbate driver shortages.

IchikawaAmong these challenges, Sumitomo Corporation focused on Dexterity, a U.S. unicorn company specializing in AI robotics software development. Spun out of Stanford University's Robotics Lab and backed by top-tier venture capitalists in the U.S., Dexterity has already built a solid track record with major logistics companies in the United States.

What is the main strength of Dexterity’s robotic AI?

OyamaFirst, it can balance quick, intuitive movements with careful, deliberate actions, much like a human Second, not only AI but also the software for each hardware, such as the robot’s sensors, arms and cameras, are being optimized and redesigned for logistics tasks.

Dexterity's CEO, Sameer Menon, has studied not only robotics but also the structure of the human brain and muscles. All development has been carried out with consideration of how to combine various movements to take optimal actions in different situations.

While other startups focus on a single function like visual recognition, Dexterity has succeeded in shortening computation processing time by optimizing the entire system, maintaining practical work speed for complex and flexible tasks. When I first saw robotic system, I was truly impressed by the variety of its applications and its flexibly to adapt to different situations.

Based on these developments, Sumitomo Corporation invested in Dexterity in 2020, and since then, we have been localizing the technology for the Japanese logistics market.

IchikawaDexterity’s unique AI software and optimized hardware design for robotic control hold significant potential not just for addressing labor shortages in logistics, but for numerous other industries as well, including construction and food. This was a major factor underpinning Sumitomo Corporation’s decision to enter the RaaS business.

Robot System that Automates Loading onto Trucks

Could you tell us more about the features and mechanisms of the robot system currently being developed with the aim of making cargo loading possible?

OyamaThis robotic system automates the loading of packages onto trucks, a task traditionally reliant on human labor and most challenging for automation. Dexterity has successfully developed a system capable of directly loading various sizes of packages into a single container, a world-first achievement.

What makes this robot system unique is its ability to stack packages coming in at high speed like Tetris without collapsing, even in confined spaces of the container.

The robot directly enters the truck’s cargo bed, where it uses cameras and sensors to analyze the shape, size and other characteristics of the packages. It then determines the appropriate placement and proceeds to stack the packages tightly, like in a game of Tetris, without leaving any gaps.

OyamaTo load the packages efficiently, the system uses an algorithm that calculates the optimal arrangement and robot movements. First, the shapes and sizes of the packages needing to be loaded are analyzed with a simulator. Based on this data, the system calculates where each package should be placed and determines the arrangement. The robot’s arm moves based on the calculations and stacks the packages accordingly.

Accelerating Practical Application Through Proof-of-Concept Trials with Key Players

What lessons and insights have you gained from the proof-of-concept trials you've been working on since 2023?

OyamaWe are conducting the proof-of-concept trials jointly with SG Holdings and Sagawa Express. Currently, we are working on localization to accommodate Japan-specific packages, labels, and truck load capacities. Packages from general customers sometimes arrive in types of packaging that we hadn't anticipated. The key to future practical use will be adjusting to unexpected situations and aligning the system to the actual operation.

IchikawaThe proof-of-concept trials consist of three phases. The first phase is to thoroughly observe the customer's operations to understand the delivery environment. The next phase involves customization of the robot system in the U.S. for the Japanese market. The third phase is bringing the robot system to Japan and testing it within actual logistics operations.

As Oyama mentioned, analyzing the on-site operations has revealed various issues. We will work to resolve them one by one as we move toward practical application.

Solving Challenges Across All Industries: The Potential of Robot AI

In July 2024, Sumitomo and Dexterity established the joint venture Dexterity-SC Japan. What was the reasoning behind this?

OyamaThere are two main reasons. The first is to speed up the establishment of a framework for providing services to Japan. Without adequate support systems in place for logistics operations running 24/7, there is a risk of operations being halted. Therefore, we believed that we needed to establish an organization that could offer robust support not only from the U.S. side but also from the Japanese side, which is why we formed the joint venture.

The second reason is our belief in the high potential of robots to solve labor shortages. We felt it was important to secure the ability to develop a broad range of solutions in-house. To solve these challenges, we need to engage with the issues confronting domestic companies and propose solutions that are suited to Japan’s logistics environment using robots.

Finally, what are the future strategies and prospects for Dexterity-SC Japan?

OyamaOur first goal is to conduct a successful proof-of-concept with Sagawa Express, our first customer, and based on that, we aim to accelerate practical implementation while helping to alleviate the labor and transport capacity issues related to the "2024 Problem in Logistics."

IchikawaDexterity’s robot AI excels at adapting to different environments and situations, allowing it to complete tasks with agility. This strength has attracted interest from industries beyond logistics.

For instance, robot AI could contribute to labor-saving and automation in other industries, such as solving problems on construction sites where robots cannot be fixed in place, or in transportation environments like railways, ships and airplanes. We feel there is great potential for this technology to help in these areas. At Dexterity-SC Japan, we are determined to continue working as a driving force in these efforts.