- TOP

- Enriching+TOP

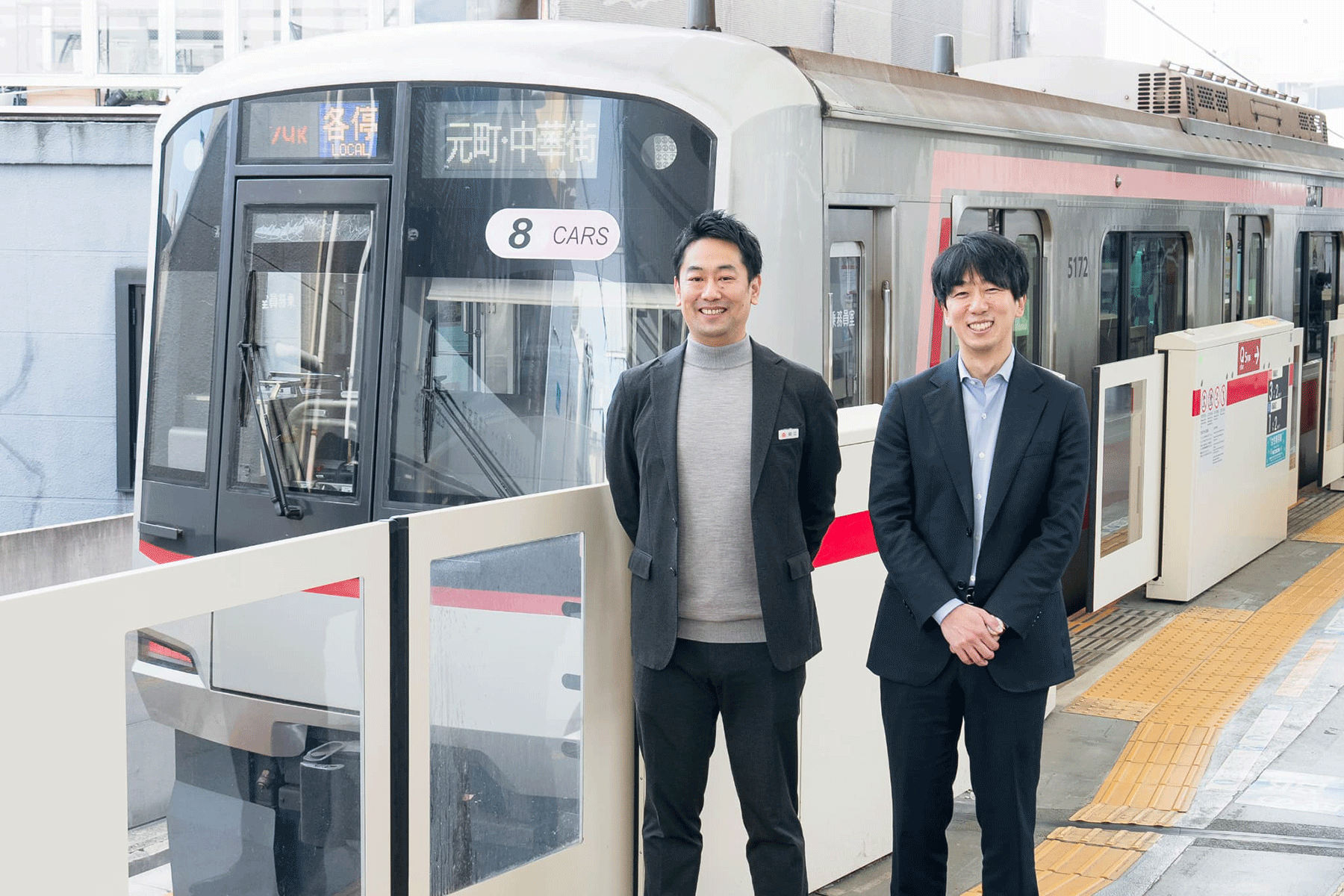

- Using AI to Streamline Track Inspections: Sumitomo Corporation and 33 Railway Operators Take on Labor Shortages in the Rail Industry

2026.2.9

Business

Using AI to Streamline Track Inspections: Sumitomo Corporation and 33 Railway Operators Take on Labor Shortages in the Rail Industry

Railways are vital to the social and urban infrastructure supporting everyday life in regional communities. Yet the industry continues to face a severe labor shortage, driven by a declining working population and difficulties in recruiting younger generations. As many experienced technicians approach retirement, improving on-site operational efficiency has become an urgent challenge. In response, Sumitomo Corporation has formed a consortium with 33 railway operators, including Tokyu Railways Corporation, to develop an AI-based solution that reduces the workload associated with routine track inspections. How was this large-scale, industry-first consortium formed? And what insights emerged during development? Today we spoke with two key individuals leading the project.

-

Head, Solution Business Development Team, 5G SBU, Sumitomo Corporation

Akinori Yamada

After working from 2006 on wireless design and development of mobile terminals for communications carriers, Yamada became involved in domestic and overseas projects from 2019 aimed at creating new businesses leveraging 5G. He joined Sumitomo Corporation in 2020, where he has been responsible for developing new businesses and services using communications technologies.

-

Manager, Innovation Section, Technology Strategy Division, Railway Business Unit, Tokyu Railways

Hiroaki Horie

Horie joined Tokyu Railways in 2007. After working in civil engineering, he engaged in medium-term management planning in the business planning division and BCP initiatives in the safety strategy division. He later worked on using data to reform track maintenance in the track maintenance division, and since October 2024 has been responsible for DX and technology development in his current role.

Digitizing Track Inspections Vital for Safe Railway Operations

What prompted this initiative?

Horie (Tokyu Railways) For several years now, the railway industry has been searching for ways to improve operational efficiency and strengthen its management foundation through DX, while continuing to ensure safe operations amid labor shortages, aging infrastructure and increasingly frequent natural disasters. At Tokyu Railways, we had already been advancing initiatives to enhance and streamline railway maintenance work traditionally carried out by people, including AI-based image analysis.

Yamada The connection between Tokyu Railways and Sumitomo Corporation originated in 5G-related business initiatives undertaken by Tokyu Railways’ parent company and Sumitomo Corporation. Building on that relationship, discussions evolved into whether we could combine Tokyu Railways ' AI image analysis efforts with our expertise in 5G to improve the efficiency of track inspection operations.

What does track inspection involve?

Horie (Tokyu Railways) Track inspection is the work of visually checking the entire track to ensure safety. Depending on the line, maintenance staff either walk the tracks or ride on trains to conduct inspections as frequently as once a week, or even daily. Beyond visual checks, inspectors rely on all their senses, including feeling vibrations through the body or listening for abnormal sounds. This work truly tests the skills of veteran maintenance staff, and daily safe railway operations depend on their expertise.

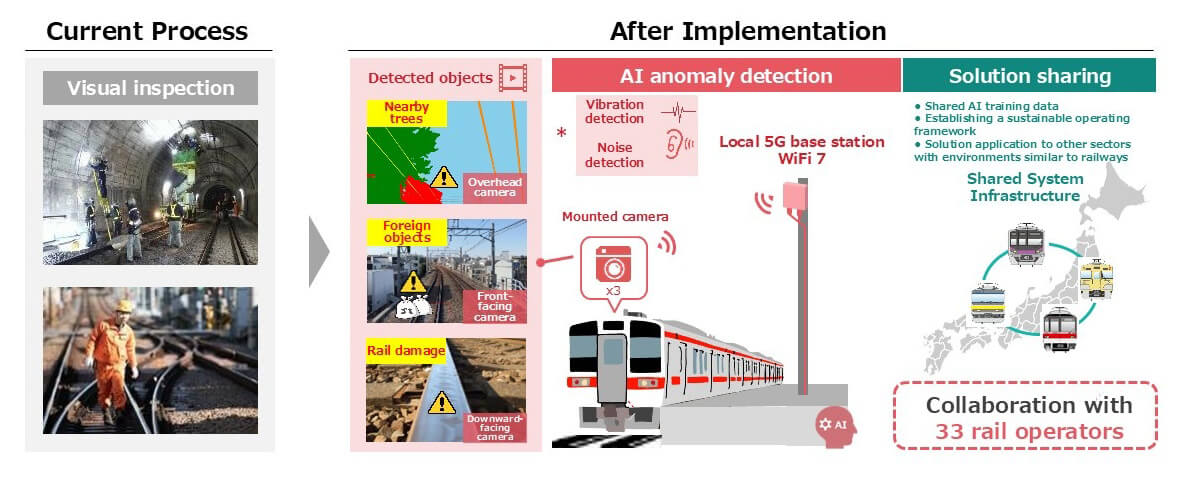

Yamada Our goal was to support this critical work with an AI solution. Cameras installed beside the driver's seat capture images of the track, which are transmitted via 5G and analyzed by AI. The system detects anomalies such as rail damage or wear, vegetation encroaching on overhead lines, foreign objects on the track, signal visibility obstructions and more. Tokyu Railways has been involved not only as a user of the completed solution, but also as a co-developer.

Horie (Tokyu Railways) The biggest challenge was how to translate the tacit knowledge embedded in track inspection – which is very difficult to quantify – into a solution suitable for on-site operations. Taking the position of both "user" and "creator" was, in our view, the quickest path to success.

33 Companies Co-Creating in a Bold, Industry-Wide Challenge

Your two companies then formed a consortium. Why a consortium?

Horie (Tokyu Railways) In a safety-first industry like railways, individual operators encounter relatively few abnormal cases, which means there is simply not enough data to train AI models. By co-creating with multiple railway operators, abnormal cases experienced by one company can be used to train the AI and shared with others. The more participants there are, the more accurate the AI becomes, and the better it can detect anomalies that a given operator has not yet encountered.

Yamada Another advantage is that we can incorporate the diverse needs of multiple railway operators from the early stages of development. This allows us to create a solution that works equally well for both urban and regional railways. In addition, by sharing AI applications, cloud infrastructure and operational frameworks, development costs can be kept down through cost sharing.

What considerations went into forming the consortium?

Horie (Tokyu Railways) Traditionally, railway operators have tended to favor self-reliance. Early on, even with similar initiatives already underway elsewhere, many operators hesitated to join a new co-creation effort.

Yamada "Consortium" and "co-creation" sound appealing, but this was an unprecedented, large-scale industry initiative, so hesitation was natural. For this reason, we leveraged Sumitomo Corporation's network to invite as many operators as possible to participate, while patiently explaining the significance and benefits of consortium-based co-creation to stakeholders at every level, from top management to on-site staff.

Horie (Tokyu Railways) Being able to share challenges that each operator had previously borne alone, and to collaborate around "data" regardless of whether the railway was urban or regional, has been invaluable. Using a Ministry of Internal Affairs and Communications demonstration-project framework also helped as it eliminated initial development costs. Identifying this framework early and bringing together so many operators reflects Sumitomo Corporation’s strong business-planning and consensus-building capabilities.

Balancing AI Accuracy and Cost Through the Consortium

What is the current development status of the solution?

Yamada The development involved a wide range of technically challenging elements, such as accurately capturing train position and converting maintenance workers' sensory judgments into data. After overcoming several hurdles, we are now conducting operational verification toward commercialization and improving usability. The onboard device equipped with cameras for track monitoring has been made light enough for train crew to carry into the cab with one hand. The solution is finally approaching a level of quality that railway operators fully recognize.

We have also kept prices as low as possible while offering a wide range of options—something that is particularly appealing for cost-constrained railway operators. For example, cameras can be either high-resolution dedicated units or smartphones; communications can use 5G or Wi-Fi; and AI models can be deployed via the cloud or on premises*1, allowing operators to choose according to their budgets.

Horie (Tokyu Railways) In addition to cost, another key feature is the ability to customize for each operator. Track deterioration rates vary depending on train speed and frequency, so criteria for judging abnormalities or repair needs can differ by operator. Our aim is to enable the AI to grow further in line with each operator's criteria, eliminating the need for ongoing outsourcing costs during operation.

Tokyu Railways ' near-term goal is to reduce the frequency of onboard inspection work from once every two days to once a week. Rather than rushing to the site whenever an issue arises, we want to first use images for spot inspections—another way this solution can be applied.

You’re just one step away from full-scale implementation. What do you think made it possible to come this far?

Yamada From my perspective as project manager, the single biggest factor was our commitment to a user-first mindset from the early stages of development all the way through to where we are now, and our determination to stay closely involved until issues were fully resolved. Agile development inevitably brings a steady stream of new requirements, and translating those into concrete solutions is never easy. Even so, by refusing to say "it can’t be done," and instead consistently asking, "how can we make this work?" the design and development teams helped foster a growing sense of unity with the railway operators in the consortium, a feeling that we were all building this together. Over time, this led to an open and constructive exchanges of ideas: "What if we tried this?" or "Let’s test that approach." As a result, we created a virtuous cycle where each new challenge served to further refine and strengthen the solution.

*1 A system where servers, network equipment and software are installed and operated in-house.

Railroads, Airports and Roads: From Full-Scale Implementation to Broader Infrastructure Applications

What are you planning next?

Horie (Tokyu Railways) This solution has already fostered a shared recognition among railway operators of the importance and necessity of collaboration. Further, these collaborative efforts go beyond track maintenance to station operations, transport operations and other cross-functional areas. For the second phase, we have launched a "Railway Depot DX" initiative that uses AI image analysis to inspect roofs, under-floors and train exteriors at depots, reducing labor requirements and dangerous work. This progress has also been possible because Sumitomo Corporation discussed with multiple railway operators to pinpoint shared challenges.

Yamada We are also considering deploying this solution to railway projects Sumitomo Corporation operates overseas, such as in the Philippines and the UK. Beyond railways, we plan to extend the system to airports for runway inspections and security purposes. We are already working with 19 airports on a project to develop a solution that detects runway anomalies.

Looking back, this initiative was not merely a matter of technical development, but a strategic challenge to nurture new business seeds while addressing social issues. The consortium-based co-creation model that leverages communications, digital and AI technologies is applicable to other fields as well: airports, roads, logistics and beyond. Our immediate focus is the full-scale implementation of DX for track inspection, but our ultimate goal is expanding to a next-generation platform that supports infrastructure across society.