VISIONS Magazine (October 2025 Edition)

SCOA Logistics Drives into the Future with Vision AI

Sumitomo Corporation of Americas is driving innovation in logistics with AI technology. In an industry where timing and accuracy determine customer success, real-time visibility has become essential. For the SCOA Logistics Group, the introduction of Vision AI marks a major advancement in warehouse intelligence — one that reduces manual effort, supports a strong safety culture and empowers data-driven operational excellence.

Seeing Everything, Reacting Instantly

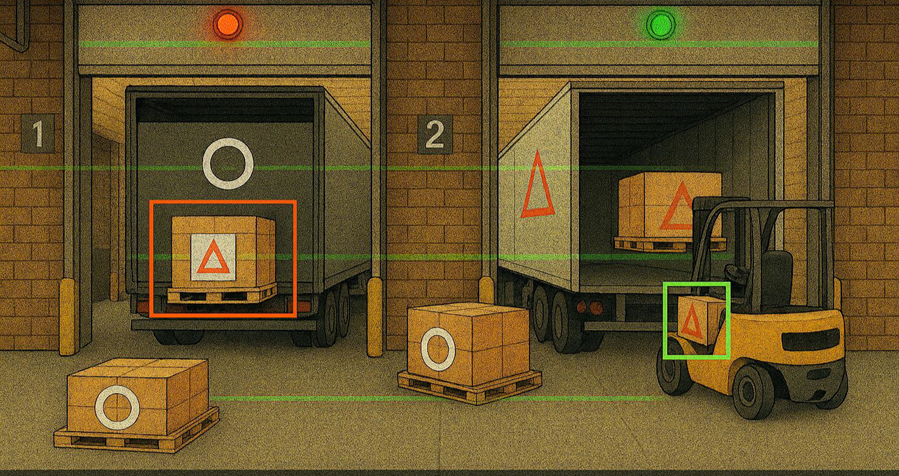

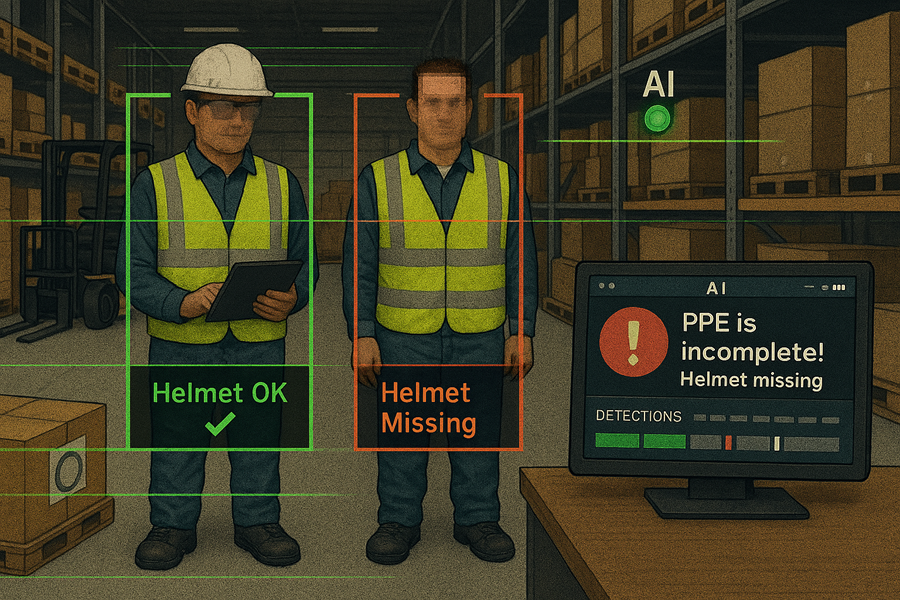

“Vision AI technology is one of the evolved versions of logistics 4.0,” explained Satoshi “Sean” Bansho, Senior Vice President of SCOA Logistics Group. “It enables the capture of an item, carton or pallet information/data without in-person scanning by bar code or QR code. It can be integrated with or without Warehouse Vision System (WMS). It provides real-time tracking and insight into inventory, equipment, and staff location and movement. The Vision AI Map illustrates a high traffic area, a high or low velocity of goods, as well as routing and tracking of pallets as an example. It detects forklift speed, logs and notifies via email or beeps when forklift has exceeded its maximum allowable speed (5 mph max), and alerts workers when forklift as close as 5 feet; or you can set other safety measures.”

With Vision AI, instead of relying solely on handheld scanners and delayed reporting, the warehouse becomes aware: of forklifts fast-traveling, of pallets lingering too long in a zone, of staff entering high-risk areas. The system logs events, generates alerts and presents a layout dashboard that lights up potential issues before they escalate.

From Scanners to Systems That See

SCOA’s logistics professionals refer to this deployment as the Warehouse Vision System (WVS) — a shift from traditional Warehouse Management Systems (WMS) toward a more capable and proactive platform.

“It is dependent upon the operational requirements; you can replace your expensive WMS with this WVS,” Bansho elaborated. “WMS captures limited data by scanning label’s bar code, QR code, or RFID code. It requires some types of bar codes. Whereas WVS does not require bar code to capture data by the image of any existing security camera in the building. WMS entails humans to gather data by zebra or Honeywell devices; on the other hand, WVS fully automated data capturing without any human interaction. Thus, it eliminates a high labor cost, human error, and additional SOP or training session. WMS operates as reactive data management; however, WVS uses the massive data for predictive demand forecasting, proactive maintenance, or optimizing space and slotting.”

By allowing existing security cameras or edge devices to capture inventory, equipment and human movement data automatically, SCOA is reducing manual scanning steps, trimming labor costs, overcoming human error and gaining continuous insight into facility operations. The leap from reactive to proactive shifts how logistics success is measured: surprise becomes planning, downtime becomes prediction, and cost becomes insight.

Preparing for Logistics 4.0

The logistics sector is evolving from Logistics 3.0 to Logistics 4.0 — a transformation anchored by artificial intelligence, connectivity and real-time systems. SCOA Logistics Group sees itself at the forefront of that shift. As Bansho puts it:

“Logistics 3.0 has been evolving to Logistics 4.0 with AI technologies,” Bansho said. “It is a good time to review what each company is spending for warehouse operations and systems. SCOA Logistics Group is here to assist evaluating what is the best practice and offers logistics 4.0 consulting service to SCOA group companies.”

What this means is simple: the warehouse of the future can see the truth of everything. SCOA is assisting its group companies adopt practices that are more visible, more efficient and ultimately more sustainable.

A Clear Vision for What Comes Next

Vision AI aligns with SCOA’s overarching mission — enabling better performance for customers while supporting sustainability through improved visibility, safety and efficiency. With the Warehouse Vision System, employees gain better situational awareness. With predictive insight, companies avoid losses before they occur. With consultancy support from SCOA Logistics Group, more partners across the Americas can begin their own transition into Logistics 4.0. In a world where logistics must be smarter, safer and faster, SCOA Logistics is helping make that future visible — one camera-frame at a time.